Bavelloni is a brand that made the history of flat glass grinding equipment. Since 1946, we have constantly supported innovation, understood as developing new products and production methods that can improve our customer’s results in terms of productivity and efficiency.

STRAIGHT-LINE EDGING MACHINES

From Bavelloni are advanced solutions designed for precise and efficient glass processing. These machines are engineered to deliver high-quality edge finishing, ensuring consistency and accuracy in various glass applications. Ideal for both industrial and artisanal use, Bavelloni’s Straight Line Edging Machines offer a blend of innovation and reliability, making them a top choice for professionals in the glass industry.

VE 350 6/6D/8:

COMPACT YET POWERFUL:

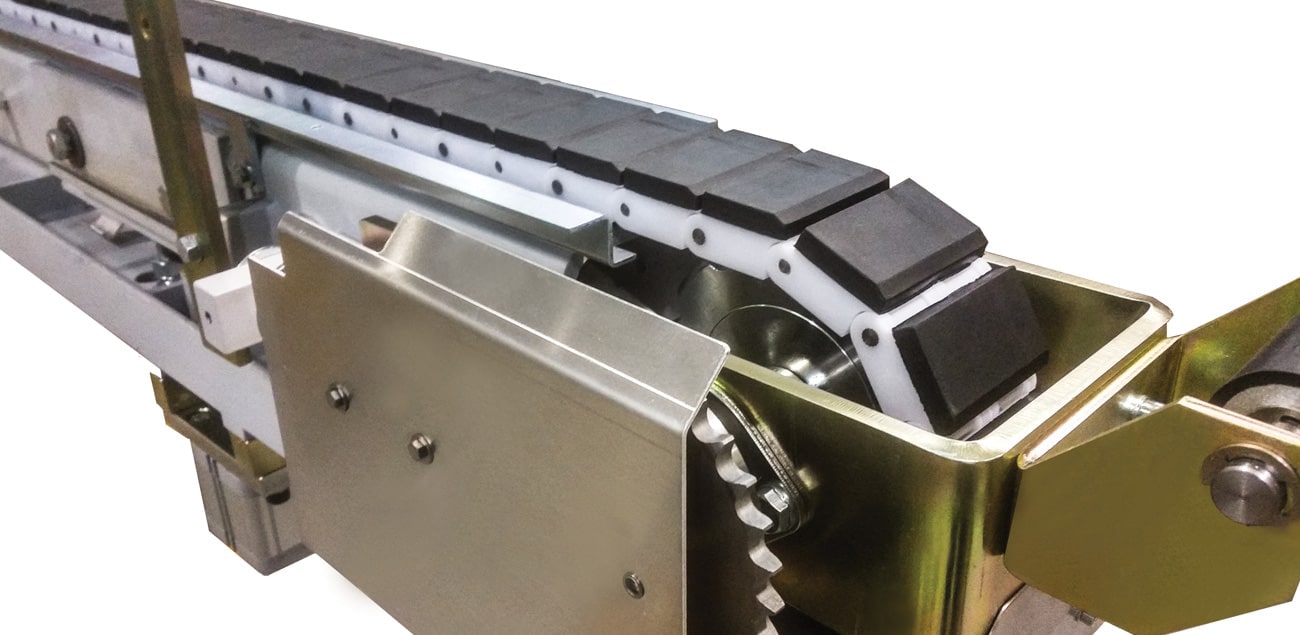

Although compact with fewer spindles, our 6 and 8-spindle edgers boast impressive loading capacity and reliability, matching the capabilities of larger models. They handle glass thicknesses up to 35 and 40 mm respectively, and weights up to 200 kg/m.

The VE 350 6 and VE 350 8 differ in arrissing: the VE 350 8 features one diamond and one polishing wheel per arris, while the VE 350 6 has one wheel for a single pass. The VE 350 6D comes equipped with six diamond wheels.

VE 350 6: Features specialized Bakelite wheels for efficient single-pass grinding and polishing of arrises, offering a cost-effective solution for quality finishing.

VE 350 6: Features specialized Bakelite wheels for efficient single-pass grinding and polishing of arrises, offering a cost-effective solution for quality finishing.

VE 350 8: Is the newest iteration of our top-selling model, combining affordability, versatility, and ease of use. This straight-line edger excels in delivering high-quality finishes, even on thicker glass..

VE 350 9-C:

MEETING NEW DEMANDS:

The VE 350 9-C features a patented, compact corner-cutting spindle that precisely removes glass corners during edging. By eliminating sharp edges, it enhances operator safety and reduces the risk of glass breakage during tempering.

VE 350 9-C: is ideal for furniture makers or small-batch architectural glass processors. Its specialized corner-cutting spindle ensures flawless 45-degree corner cuts at any operating speed..

VE 350 9-C comes with three polishing wheels for flat edge finishing, ensuring exceptional end-product quality.

VE 350 11:

TOP-TIER PERFORMANCE:

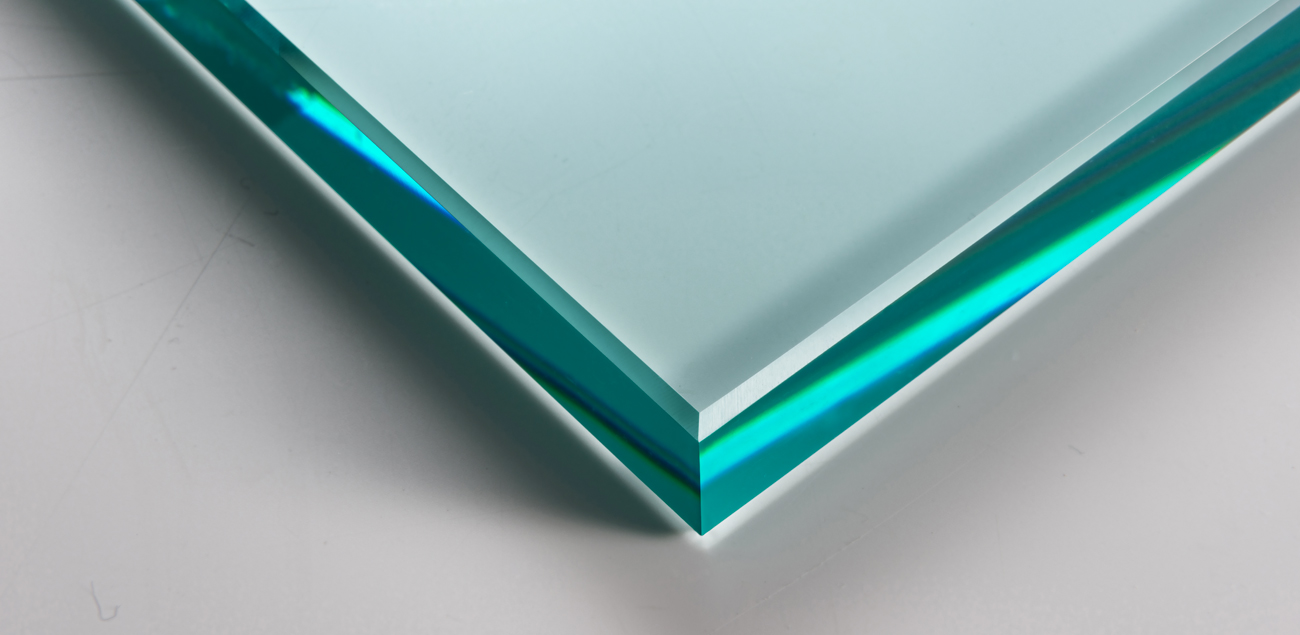

The VE 350 11 straight-line edger offers unmatched flexibility, productivity, and finishing for both float and laminated glass. With its versatile toolset, it delivers optimal results on all glass types up to 40 mm thick.

With three diamond wheels and four polishing wheels, the VE 350 11 ensures top-quality flat edges. It also offers the flexibility to install diamond, Bakelite, polishing wheels, and felt for liquid cerium oxide polishing.

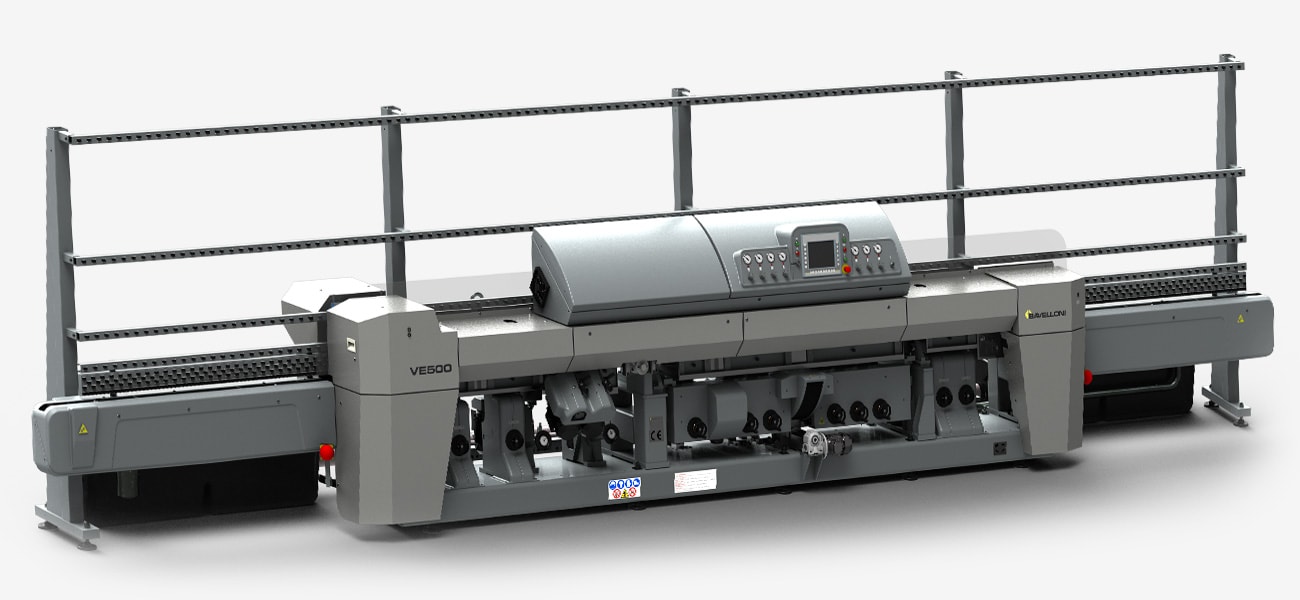

VE 500 11:

EVOLUTION ON A LARGE SCALE:

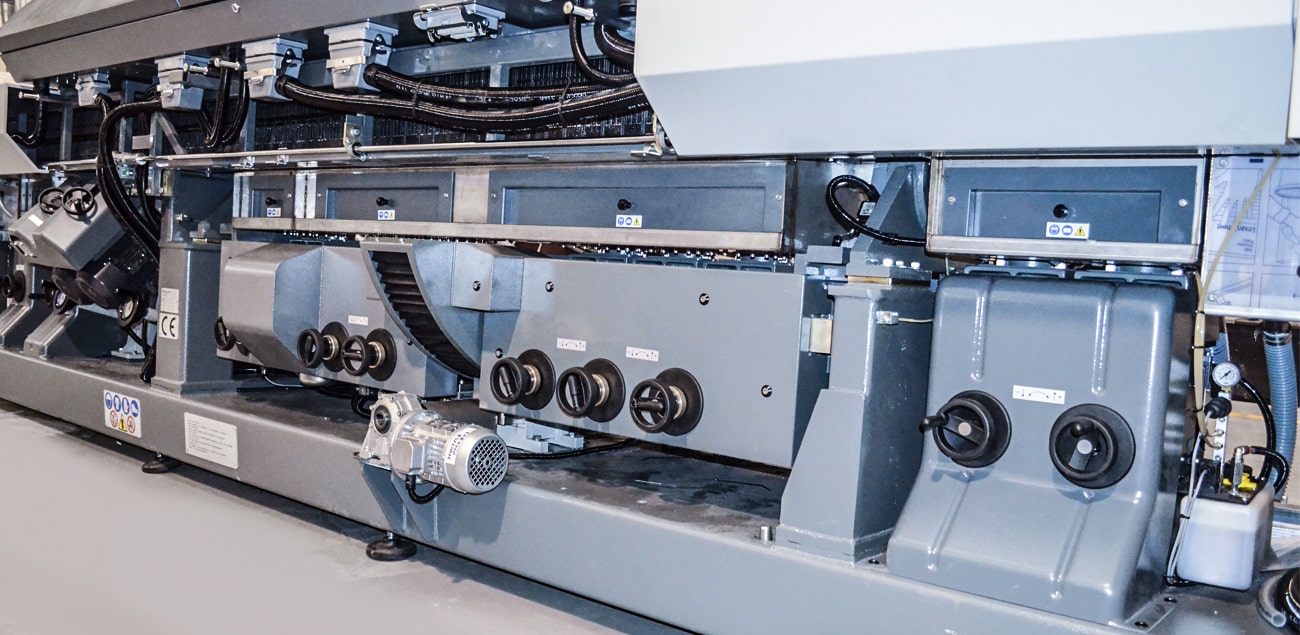

The VE 500 11 is Bavelloni’s response to the demands of modern architecture, with its growing need for large glass sheets. Boasting a robust structure for heavy loads, a large intuitive control panel, and a wide array of options, this machine embodies versatility and reliability.

Setting and control by means of the new operator interface have never been so easy. A big screen (10” touch screen) is used to improve the display of information.

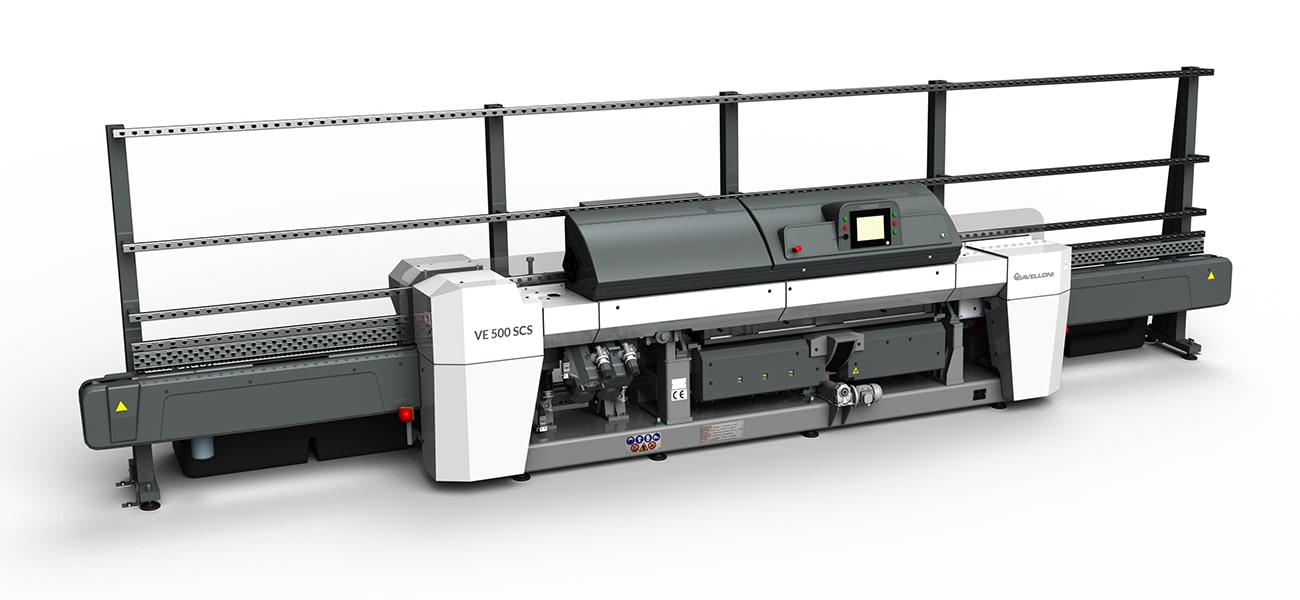

VE 500 11/V10/V14 SCS:

ELEVATING AUTOMATION:

The SCS variants of the VE 500 11, VE 500 V10, and V14 straight-line edging machines introduce an advanced spindle control system for enhanced automation.

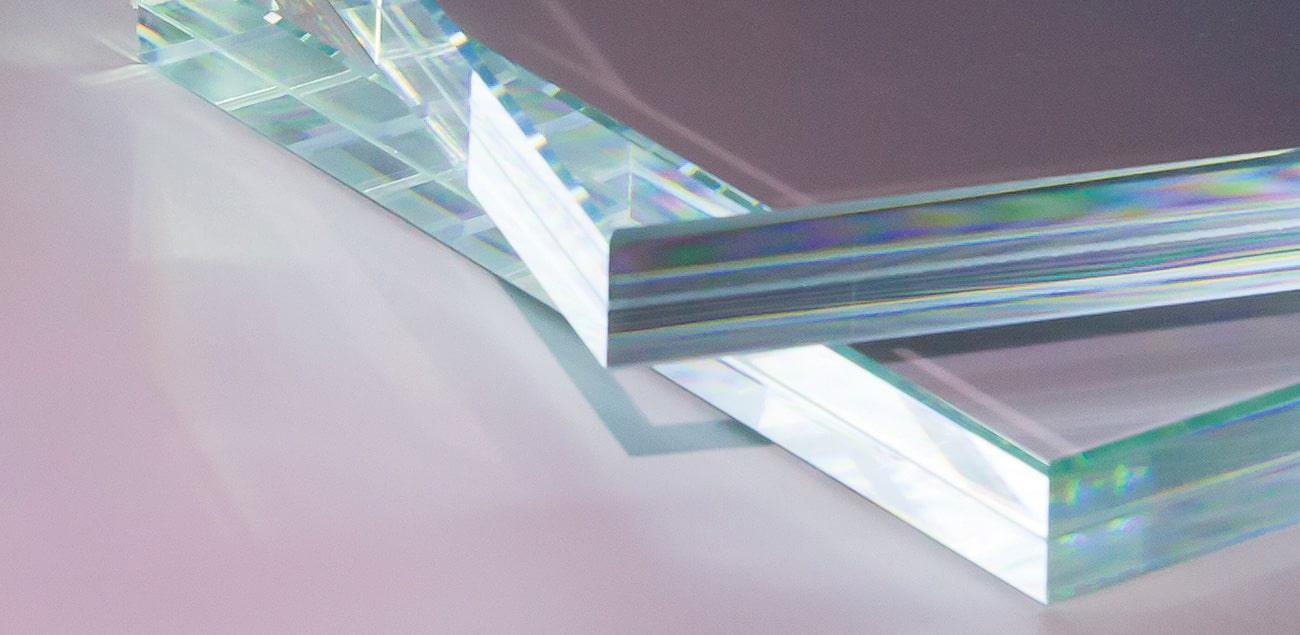

VE 500 V10 and V14:

TECHNOLOGY AND PERFORMANCE:

The V10 and V14 mitering machines, designed for processing chamfers with variable angles from 0° to 45°, offer significant advantages in today’s market. Engineered to handle heavy loads, these machines can be customized with a wide array of options to meet diverse production needs.