Bavelloni is a brand that made the history of flat glass grinding equipment. Since 1946, we have constantly supported innovation, understood as developing new products and production methods that can improve our customer’s results in terms of productivity and efficiency.

Bevelling machines for glass

Bavelloni’s Bevelling Machines are designed for precise and efficient glass beveling. These advanced solutions ensure high-quality edge finishing, suitable for various glass applications. With a focus on innovation and reliability, Bavelloni’s Bevelling Machines are ideal for both industrial and artisanal use, delivering consistent and accurate results in the glass processing industry.

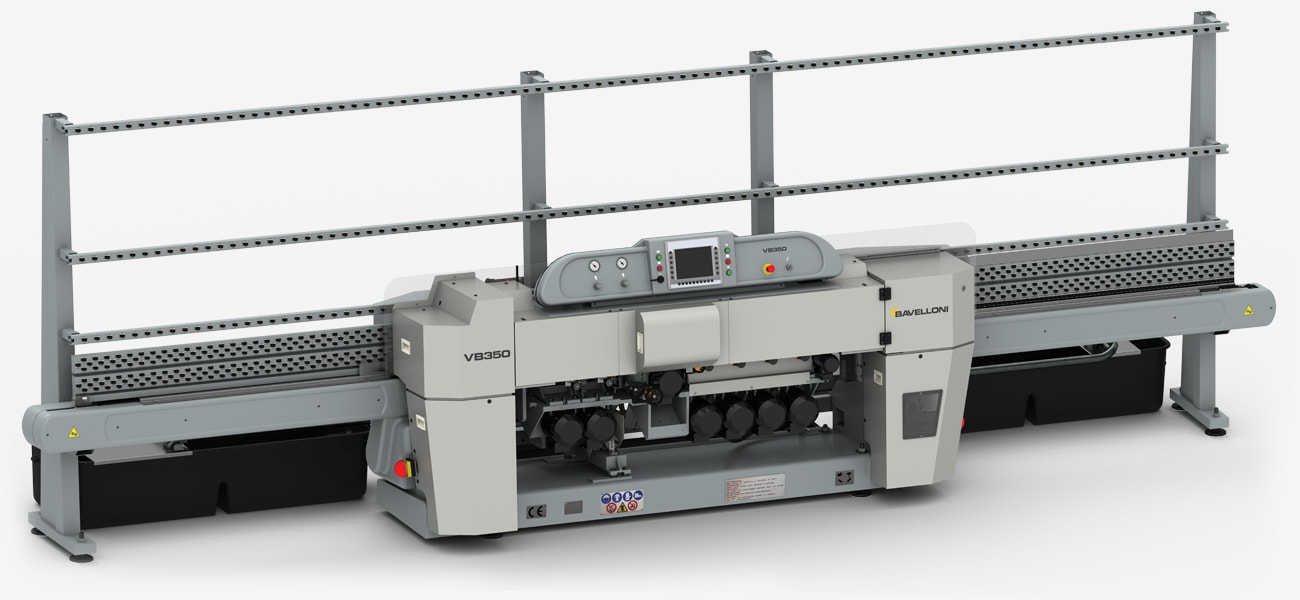

VB 350 CN and CNS:

COMPACT AND EFFICIENT:

The VB 350 is our most popular bevelling machine, striking an optimal balance between investment and productivity. It incorporates advanced technical features from our top models, making it a favored choice for many businesses.

While operating at a slightly slower speed, the VB 350 delivers high-quality results, reduces investment and operating costs, and offers ease of use and lower operational demands.

Offering exceptional grinding quality, the Bavelloni VB 350 is an ideal solution when high productivity rates are not the primary concern.

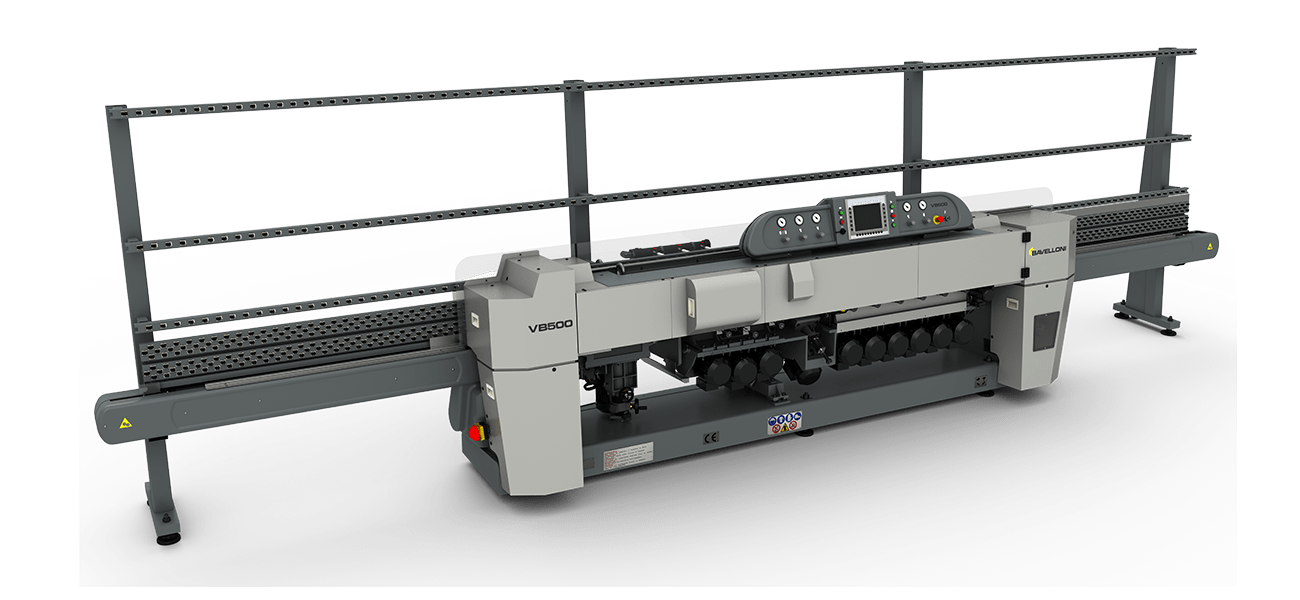

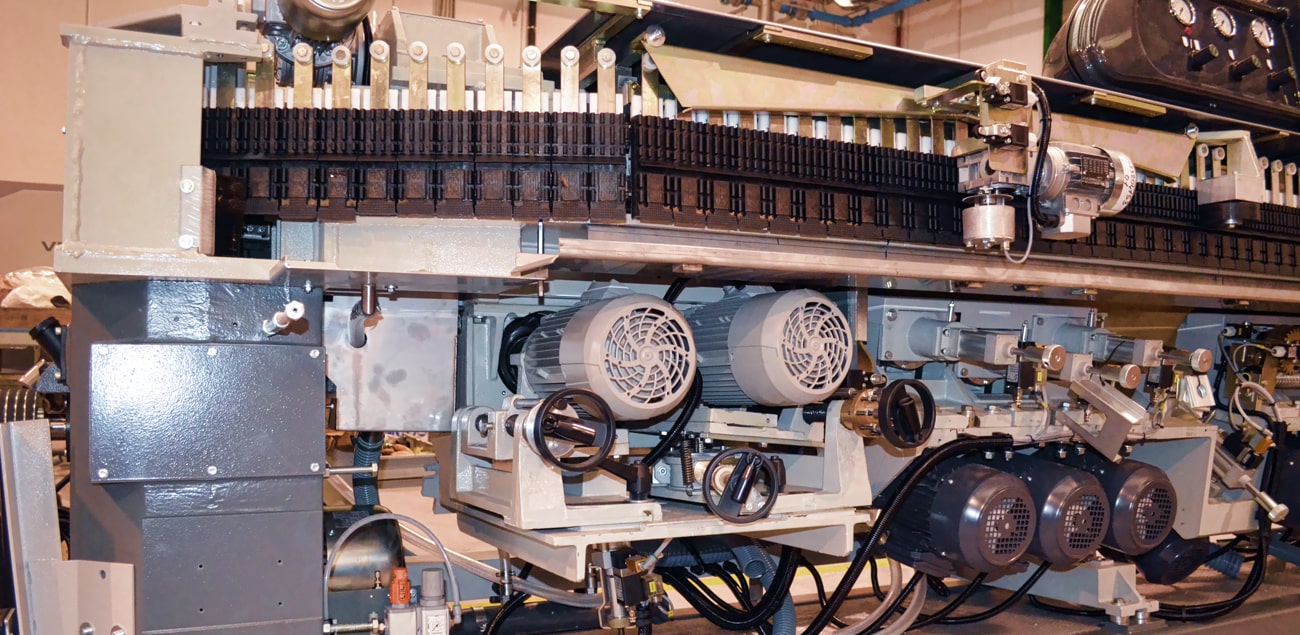

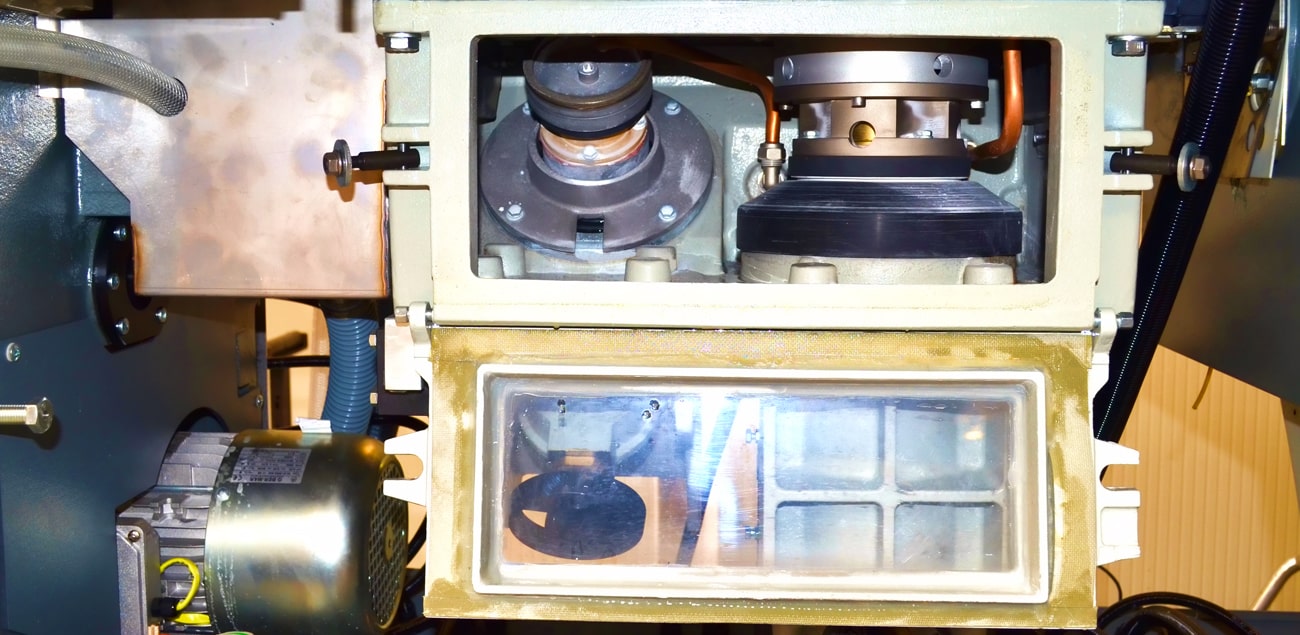

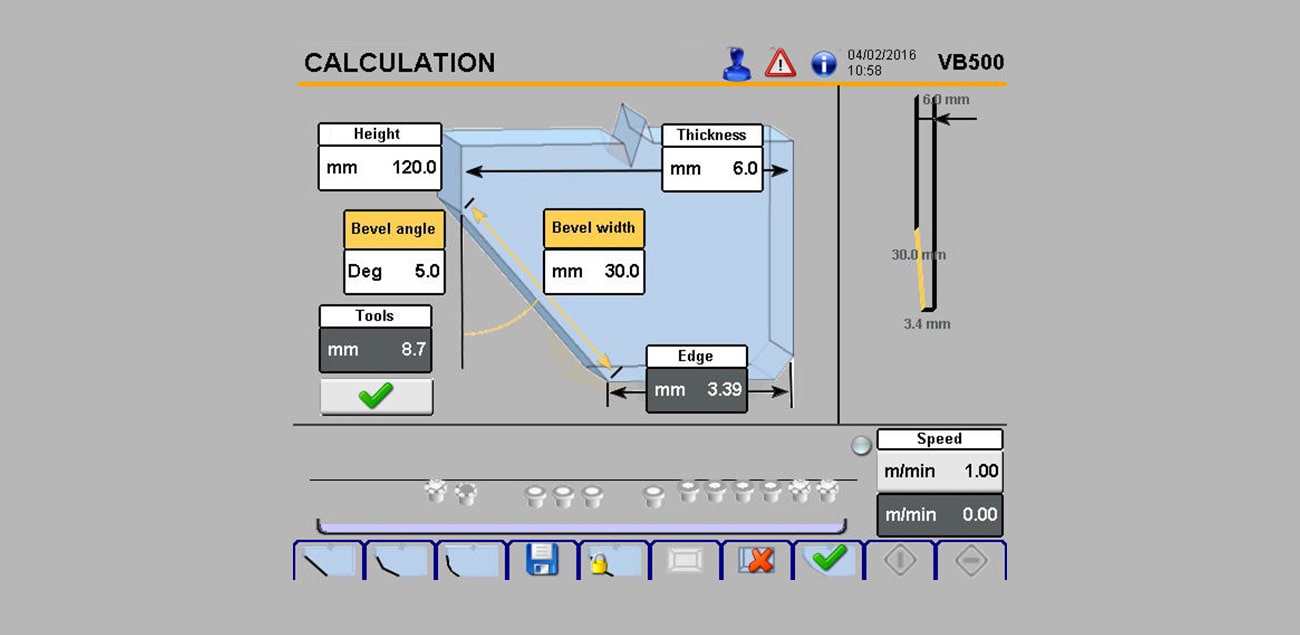

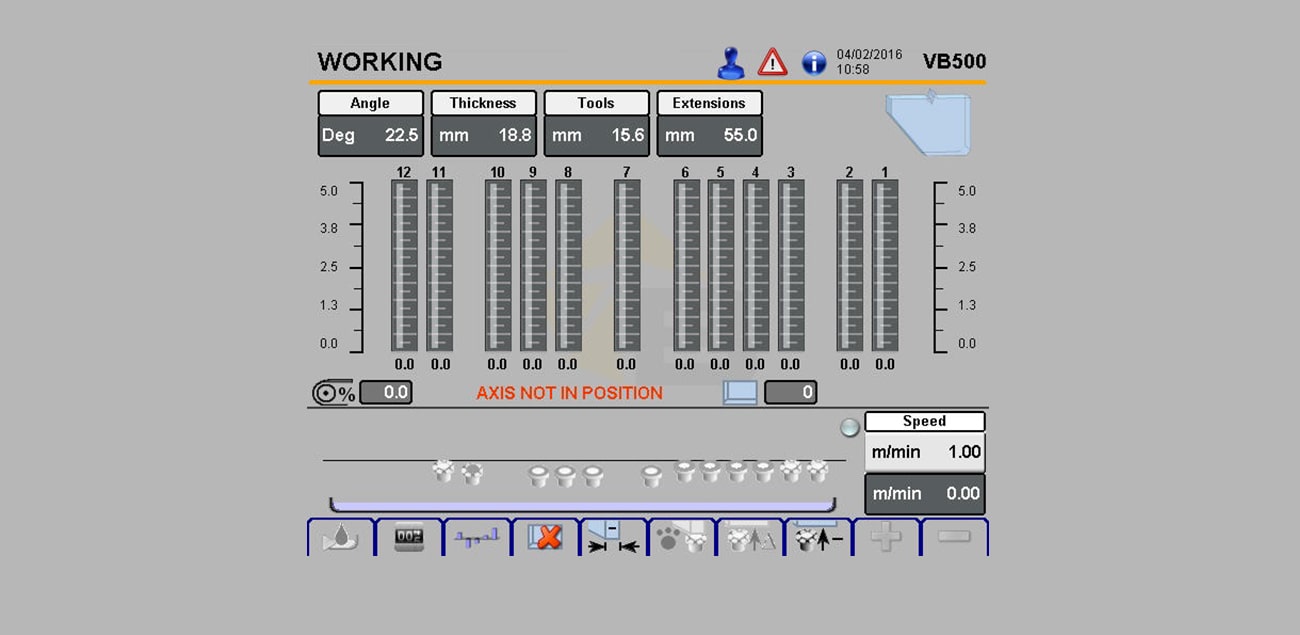

VB 500 CNP and CNS:

MEETING ALL YOUR NEEDS:

The VB 500 represents the latest evolution in a range that has set the industry standard for nearly four decades. Trusted by companies producing beveled glass at industrial scales, the VB 500 is renowned for its high productivity, exceptional quality, and extremely low operating costs.

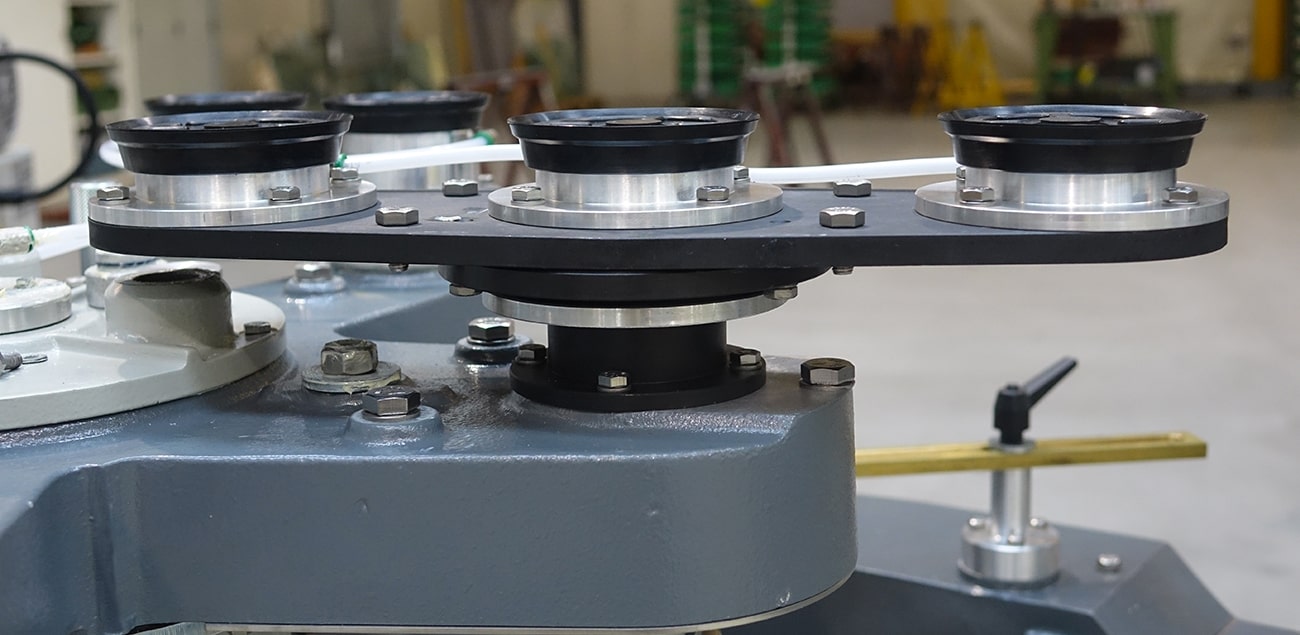

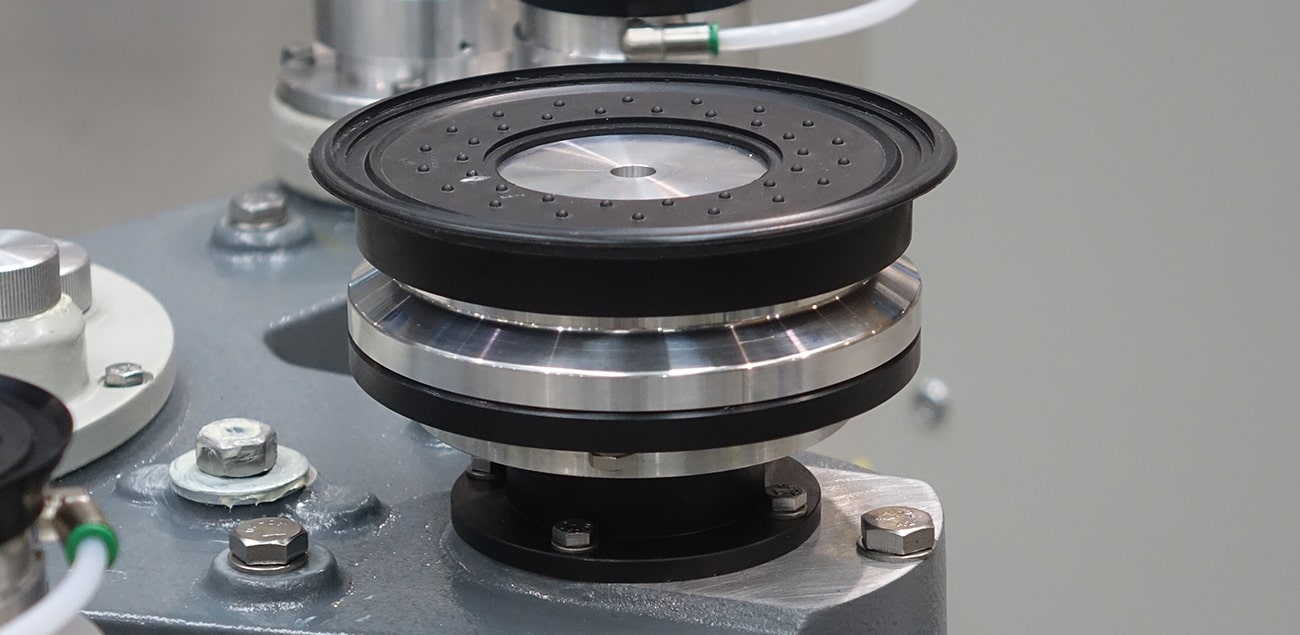

The VB 500 comes in two configurations to meet specific edge finishing requirements:

CNP model: Equipped with three wheels to grind the remaining edge, producing a polished flat edge with arrises.

CNS version: Uses two peripheral wheels to grind the remaining edge, creating a polished pencil edge shape.

Combining exceptional end-product quality with high productivity, the VB 500 consistently delivers unmatched bevel precision over time.

SB10:

TRUSTED BY OVER 2000 CUSTOMERS:

The SB 10 is undoubtedly the best-selling horizontal semi-automatic machine for edge grinding, polishing, and beveling of shaped glass in the industry. With over 2000 units installed, the SB 10 is a staple in glass factories worldwide.