Bavelloni is a brand that made the history of flat glass grinding equipment. Since 1946, we have constantly supported innovation, understood as developing new products and production methods that can improve our customer’s results in terms of productivity and efficiency.

Cutting tables for glass

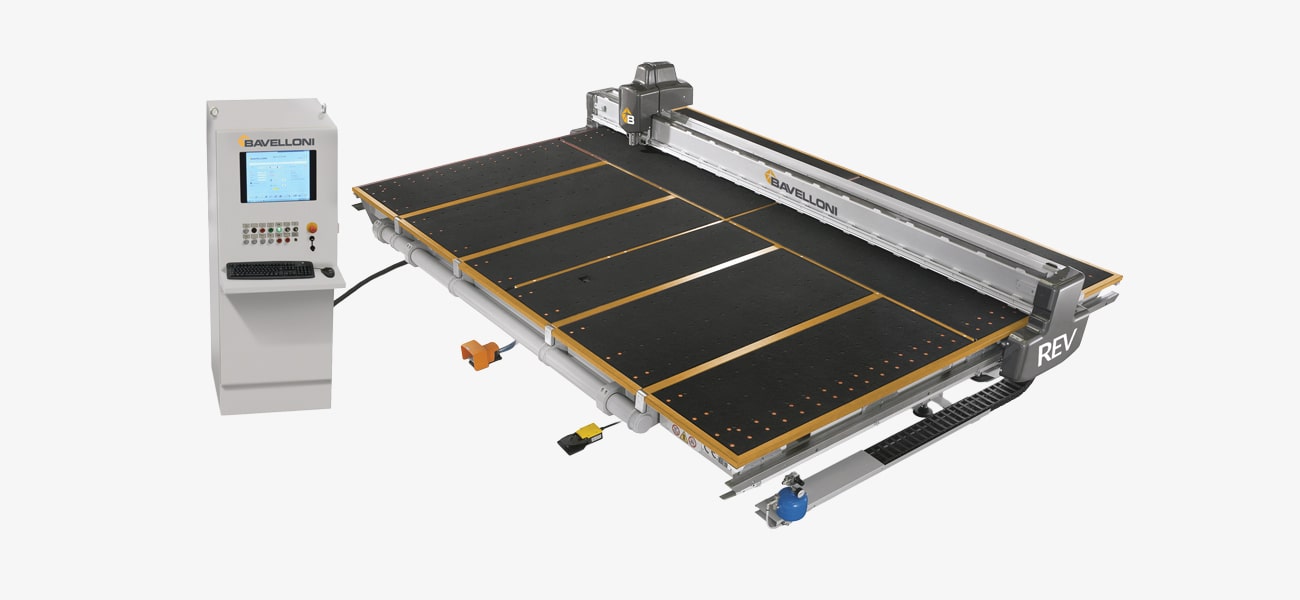

Bavelloni has been the first Company to supply cutting tables with truly innovative features. With unique patented solutions, REV series for float glass cutting provides unmached performance and proven reliability.

REV 372 SR:

OPT FOR THE ORIGINAL:

The REV 372 SR is a stand-alone cutting table with manual loading, boasting a compact footprint and robust components for consistent performance and lasting reliability. Despite numerous imitations, it remains the industry benchmark and an ideal solution for glass companies seeking uncompromised quality.

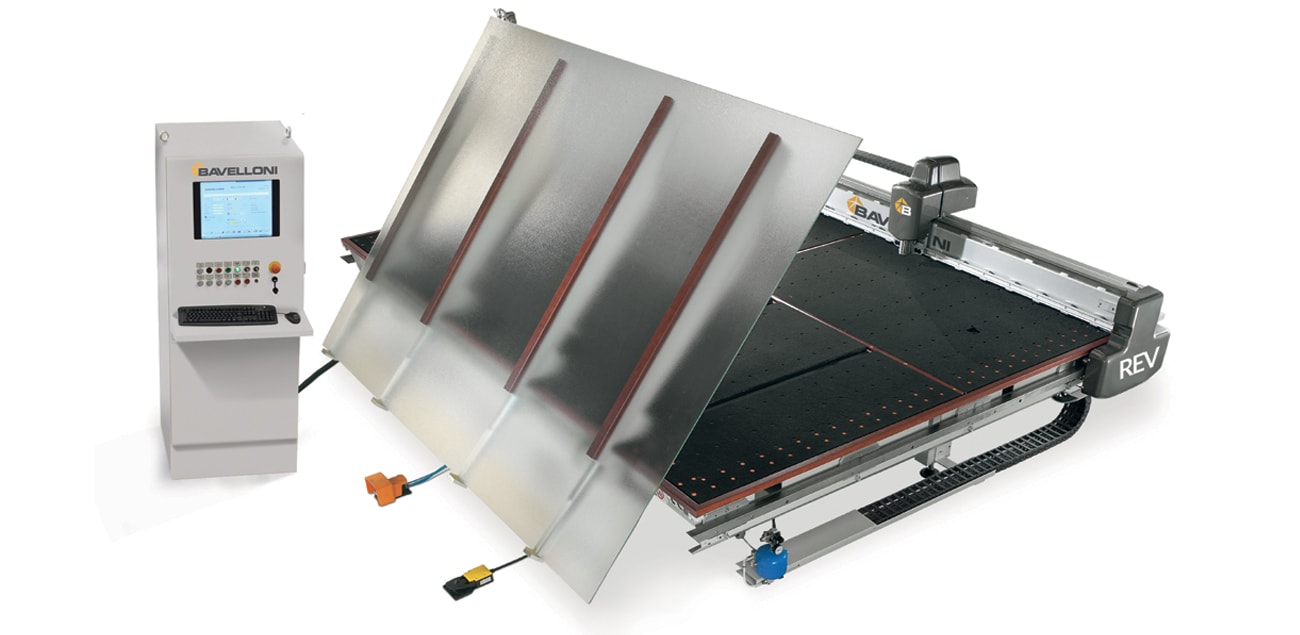

Plug & Play Simplicity

The REV 372 SR cutting table offers easy installation and operation, with electrically driven, maintenance-free loading forks.

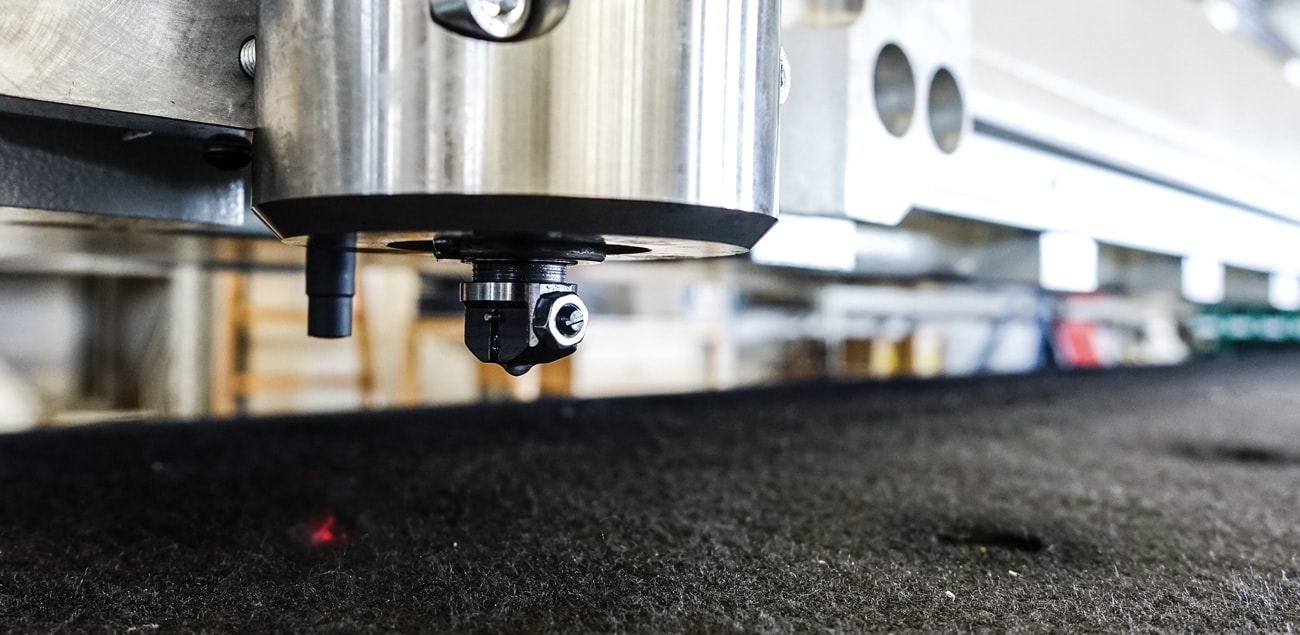

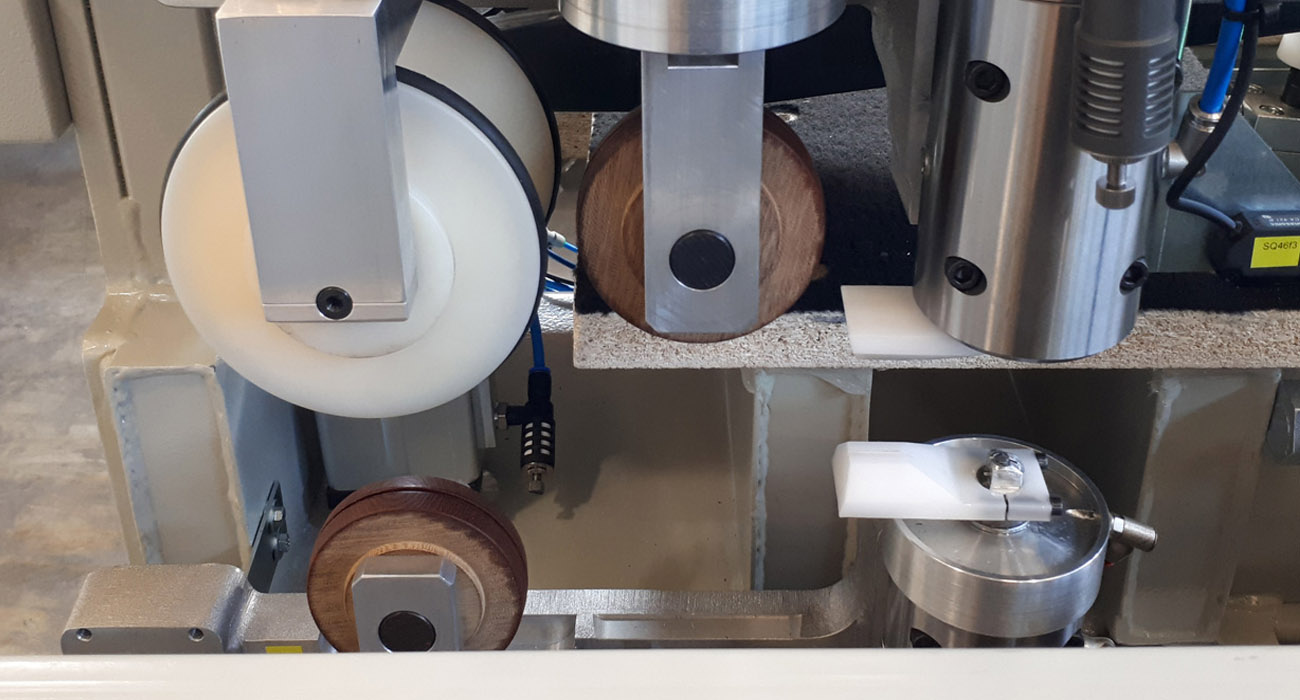

Device for low-e removal

The REV 372 SR can be equipped with an automatic low-e coating removal device that uses a cup wheel.

Advanced Automation

The REV Series features a sophisticated automation system that combines the power of a professional Numerical Control with the convenience of an industrial PC running on Windows®. The user-friendly PC interface serves as the sole control point for the machine.

Standard Features

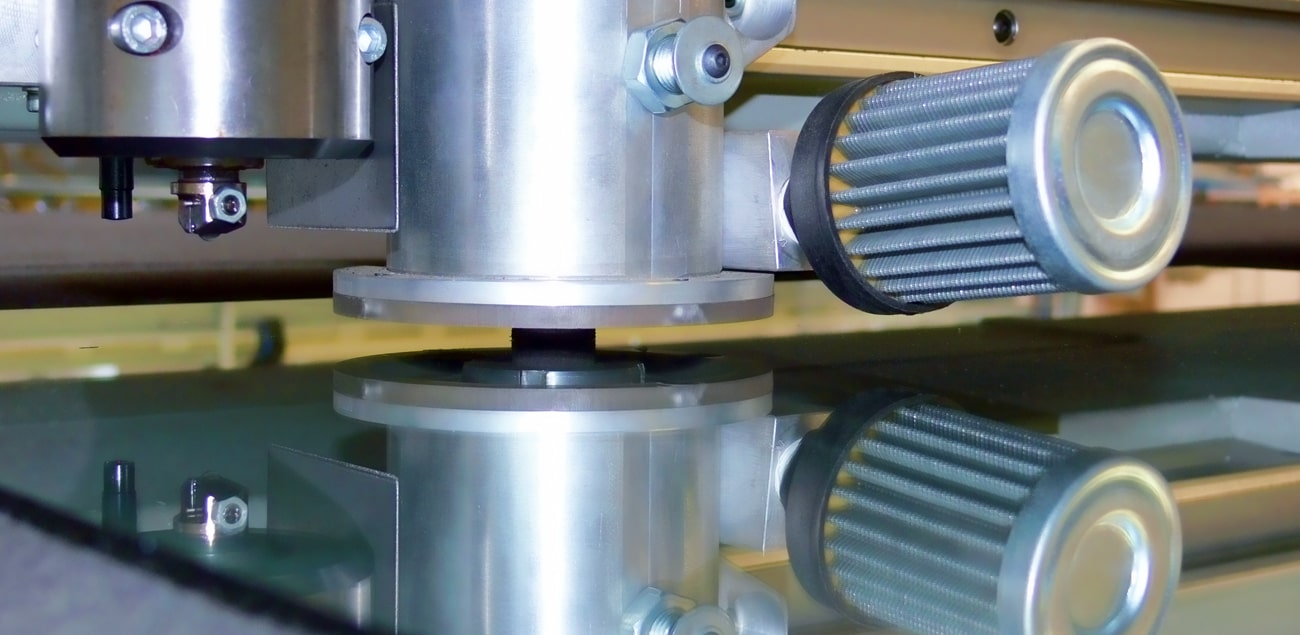

The REV Series includes automatic glass thickness detection, a laser for template reading and automatic squaring, automatic adjustment of cutting pressure based on glass thickness and radius size, and a program for mirror-cutting laminated glass as standard features.

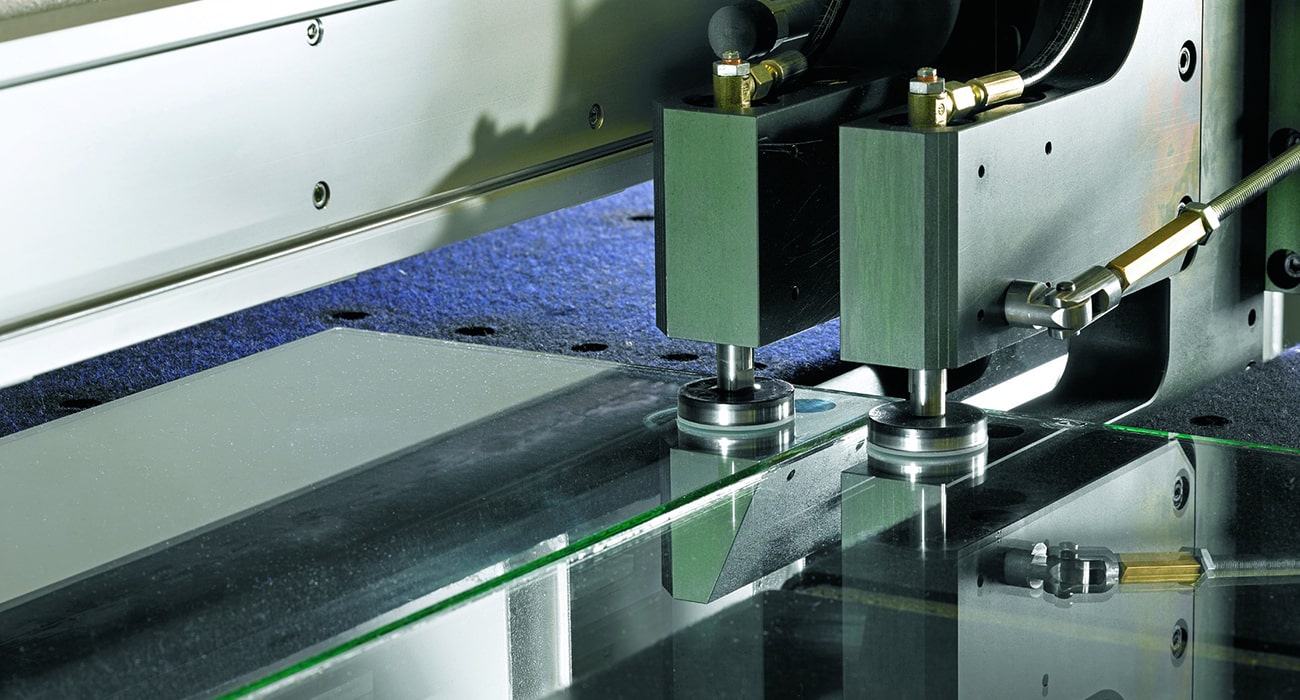

Premium quality cut

The REV 372 SR delivers exceptional cutting across all glass thicknesses, including open cuts on 10mm glass and easy breakouts on 19mm glass. Its advanced cutting head ensures excellent 90° edge quality, reducing the need for heavy grinding and additional processing time.

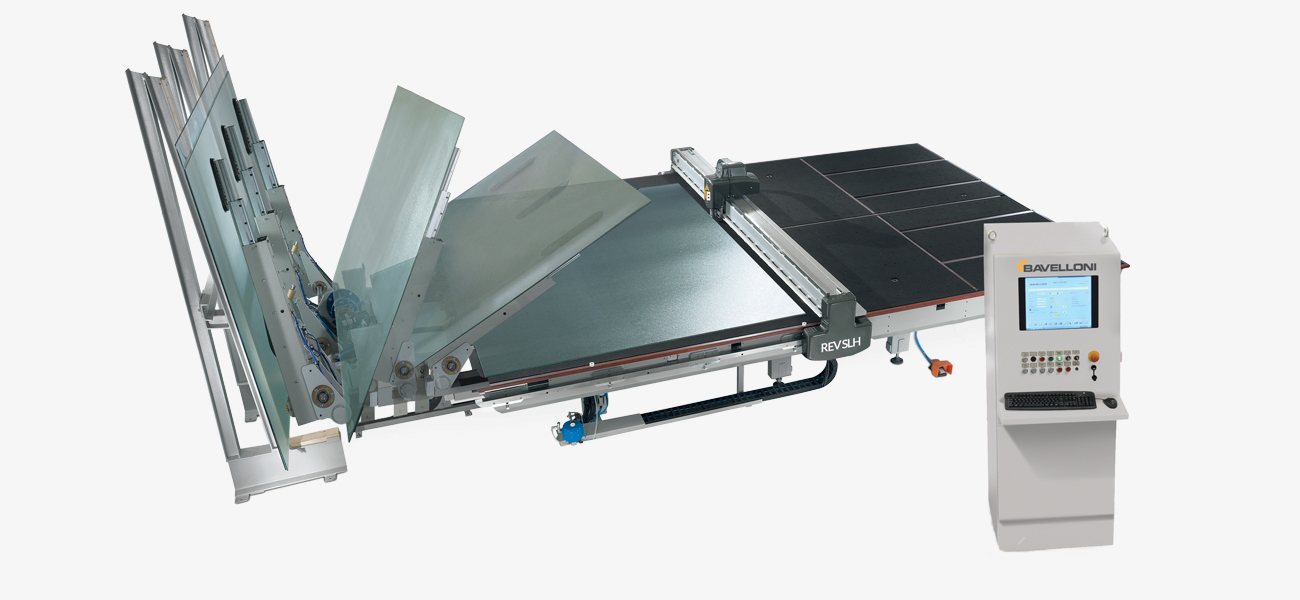

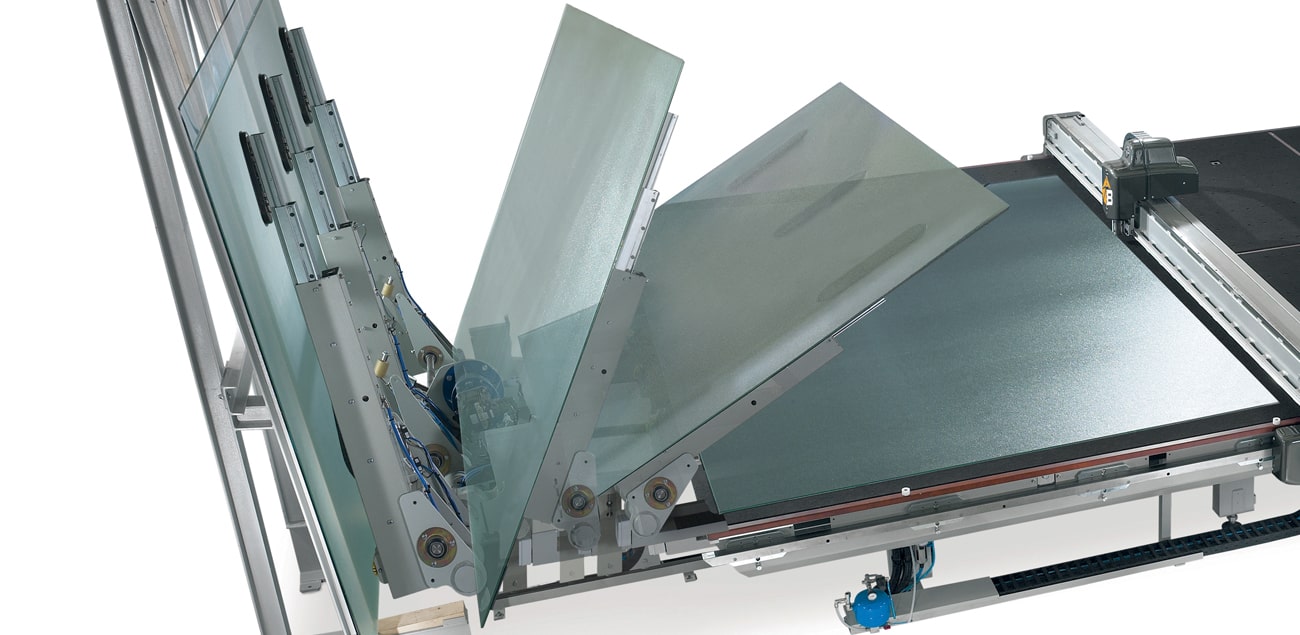

REV 370 SLH:

REV 370 SLH is a cutting line composed of an auto-loading cutting table and a breaking table. With extremely compact dimensions compared to traditional solutions, the SLH line ensures high productivity thanks to the innovative solutions adopted, as well as high control over cutting speed and precision.

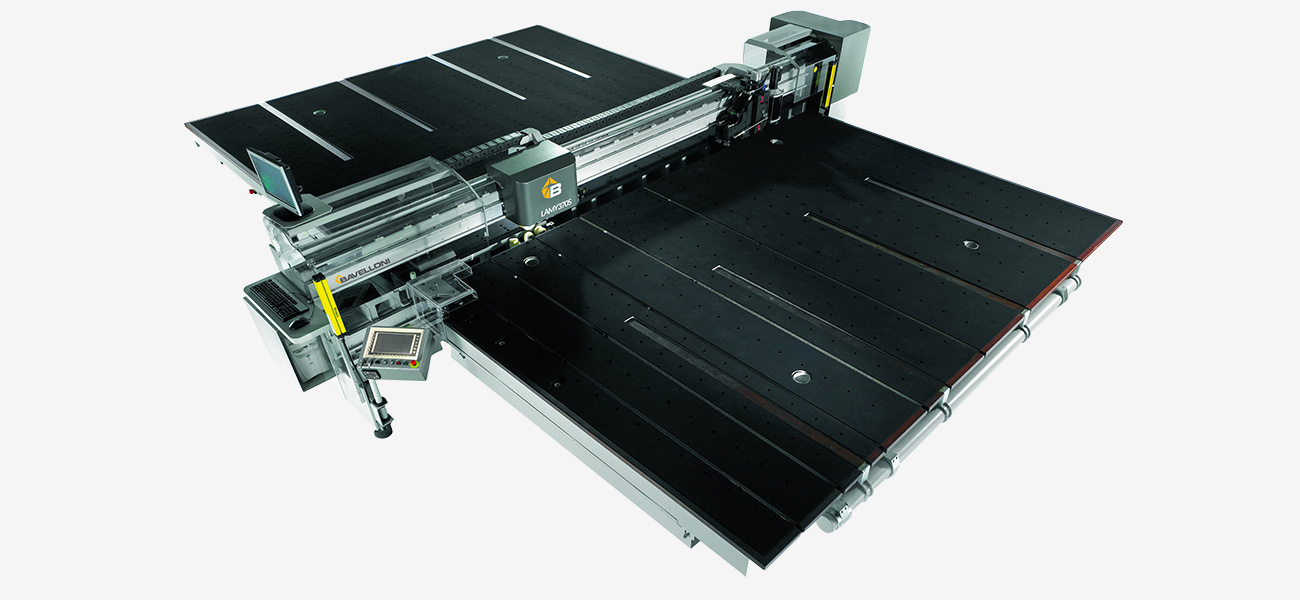

LAMY 370 S:

Lamy 370 S: Versatile and Efficient:

The Lamy 370 S is designed for cutting, breaking, and detaching laminated glass, making it ideal for low-e glasses. Its special separation pliers prevent coating damage during detachment. The single bridge structure ensures an obstruction-free working area, simplifying glass handling, roller changes, and machine cleaning.

Efficient Trimming Capabilities:

The Lamy 370 S can perform automatic trimming up to 60 mm, even on thick glass (up to 8+8+4.56 mm), significantly reducing scrap.