Bavelloni is a brand that made the history of flat glass grinding equipment. Since 1946, we have constantly supported innovation, understood as developing new products and production methods that can improve our customer’s results in terms of productivity and efficiency.

Double-edging machines for glass

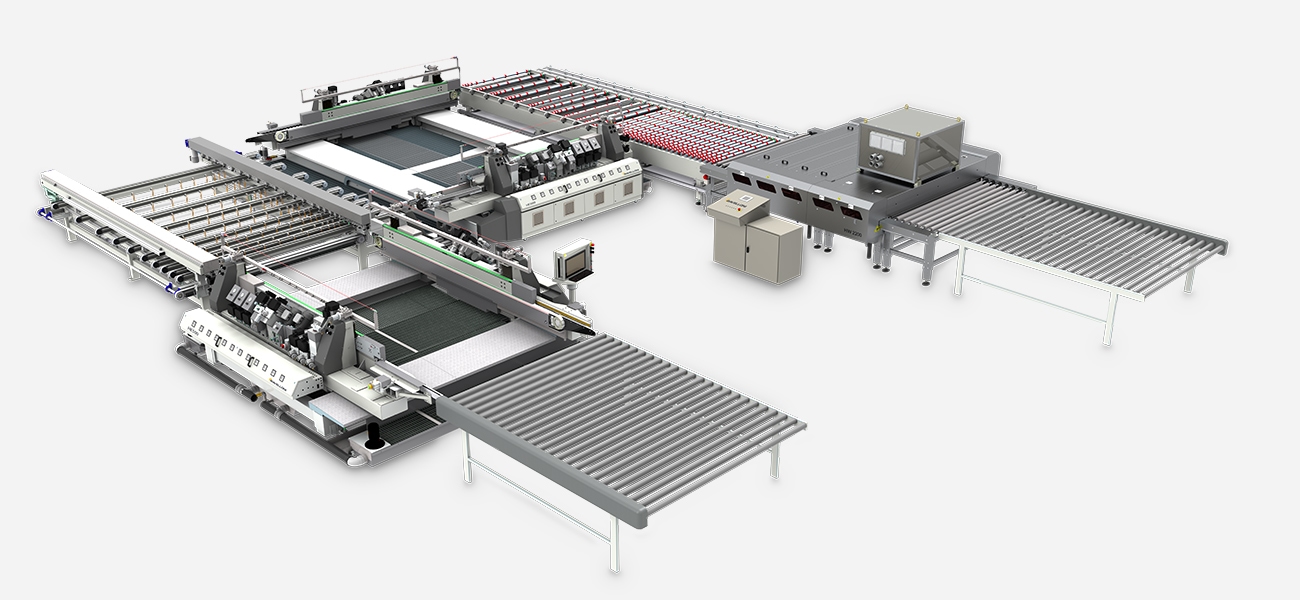

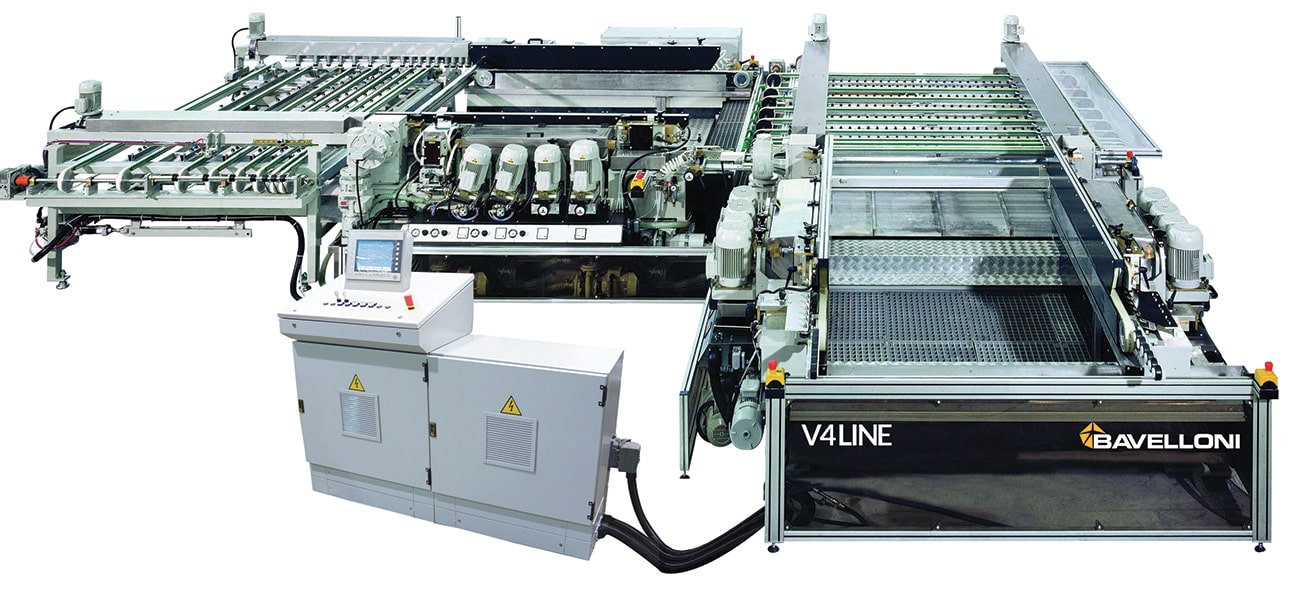

Double-edging grinding has long been a cornerstone of Bavelloni technology. With three decades of expertise in the field, Bavelloni has designed hundreds of plants worldwide, tailored to meet the specific needs of its customers. This unmatched knowledge has been cultivated through close collaboration with clients, who can depend on Bavelloni as a trusted partner to implement the best solutions.

HE500

DUAL-EDGE GRINDERS WITH CUP WHEELS FOR LARGE-SCALE PRODUCTION:

The HE500 series stands out with its productivity, precision, and versatility, featuring dual-edgers with cup wheels designed to grind flat edges with arrises. Available in four models based on the number of spindles and dimensions up to 3300×6000 mm, the HE500 models represent the evolution of a double-edging line that has enjoyed great success for 25 years. Equipped with the latest technologies, these high-end products meet the demands of the most discerning customers. Additionally, their integrated electrical box optimizes space and enhances ergonomics.

UNPARALLELED CONFIGURATION FLEXIBILITY

Bavelloni’s double-edging lines offer unlimited configuration options, tailored to the layout, maximum workable sizes, glass profiles, and automation level. A wide array of optional accessories, including automatic loaders and unloaders, tilting tables, rollers, and transfers, enables the creation of customized solutions to meet the unique needs of each customer.

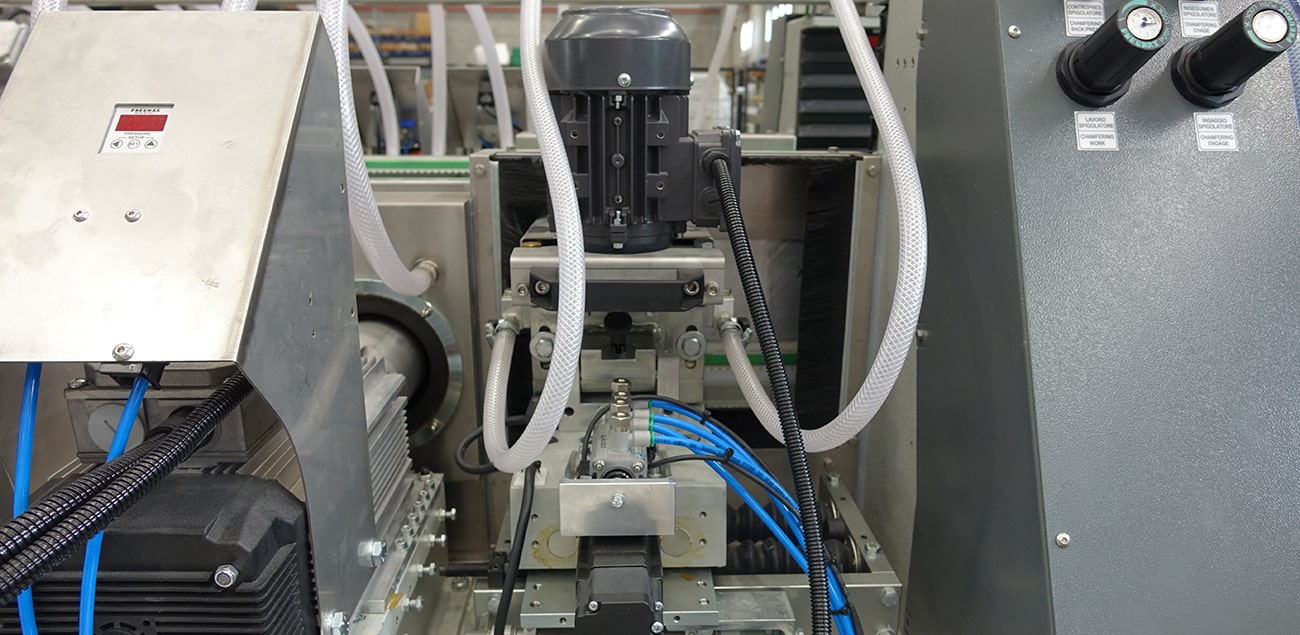

ADVANCED FUNCTIONALITY CONTROL

All double-edging lines are equipped with state-of-the-art control and management systems. The user-friendly controls can be seamlessly integrated into customers’ computer systems, streamlining the communication of production parameters. Additionally, all plants can be outfitted with teleservice functionality for enhanced management of service activities.

TAILORED CUSTOMIZATION

A wide range of options is available to configure the double-edgers to meet specific requirements. These include tool presetting, various levels of automation, corner cutting spindles, and automatic intermediate bars, among others. This flexibility ensures that each machine can be tailored to the unique needs of the customer.

IDEAL FOR BOTH SMALL AND LARGE BATCHES

Historically, double-edging machines were considered suitable only for large production batches. However, thanks to innovative control systems and automatic settings, these machines can now deliver maximum benefits for any production size, including those that require frequent format changes.

RELIABLE PERFORMANCE

Bavelloni double-edgers are the top choice for companies requiring flexibility and high production capacity. Often operating 24/7, these machines can grind thousands of meters daily with minimal downtime, ensuring reliability even in the most challenging conditions.

MINIMIZED SETUP TIMES

Bavelloni has focused on reducing setup times for format changes. All necessary settings can be managed manually or automatically via the control device. For instance, the optional tool presetting feature ensures perfect wheel alignment without operator intervention.

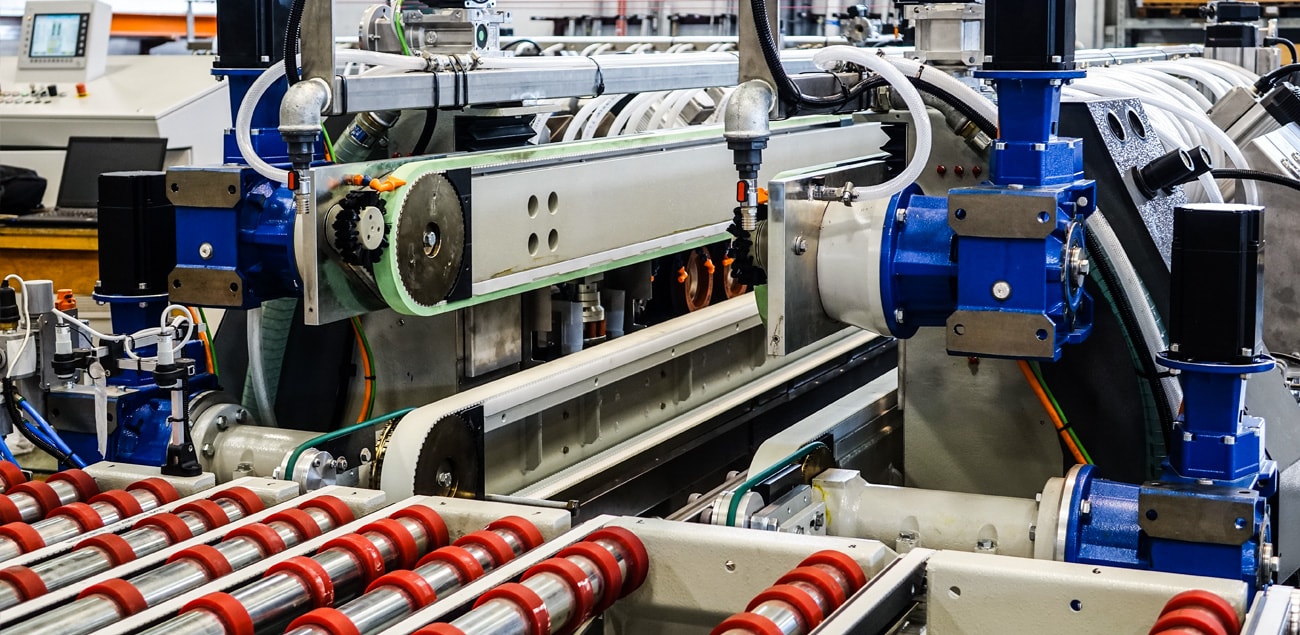

V LINE:

DUAL-EDGE GRINDERS WITH PERIPHERAL WHEELS:

The V series dual-edgers are ideal for processing small to medium thickness glass with pencil edge shapes at high speeds. Particularly suited for household appliances, refrigeration, and solar industries, these lines excel in high production rates, reliability, and user-friendliness.

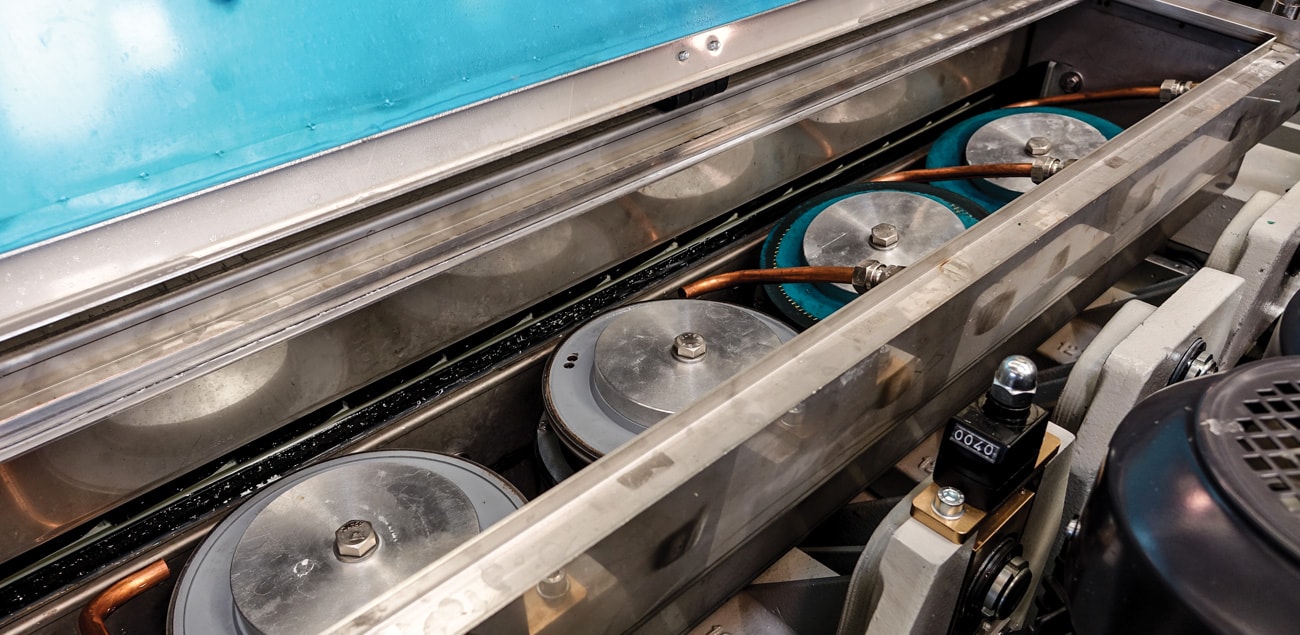

SIMPLIFIED TOOL REPLACEMENT

In the V series dual-edgers, the wheels are mounted upwards in a stainless steel box, making tool changes convenient and ensuring perfect water containment.

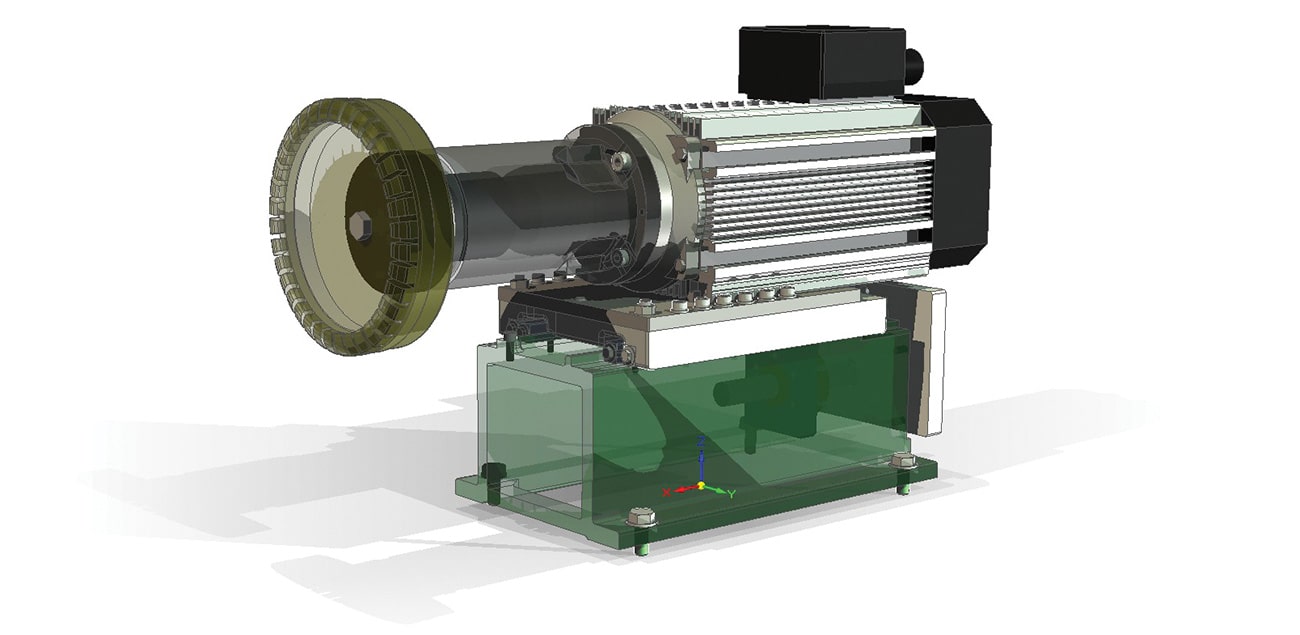

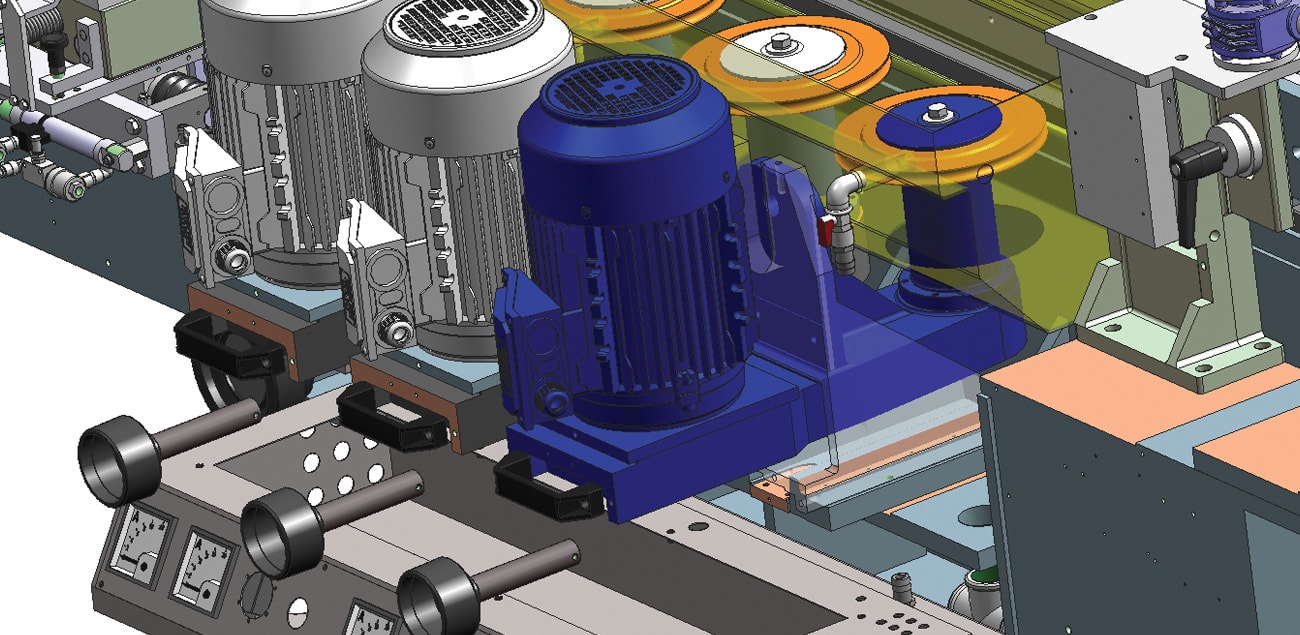

PATENTED HIGH-PERFORMANCE SPINDLES

For the V series, Bavelloni has developed patented spindles with a separate motor connected via a transmission belt. This design eliminates vibrations and allows customers to modify tool speeds by simply changing the pulley diameter.