Bavelloni is a brand that made the history of flat glass grinding equipment. Since 1946, we have constantly supported innovation, understood as developing new products and production methods that can improve our customer’s results in terms of productivity and efficiency.

Drilling/Milling machines for glass

The VT 1250 is a world-class double-headed drilling machine, renowned for its durability, accuracy, and reliability, making it a top choice for thousands of companies. The VDM 1636 CN is a versatile vertical drilling-milling machine with double heads and opposing spindles, capable of executing complex cycles in a single station. It is ideal for fabricating doors and various architectural applications, both internal and external.

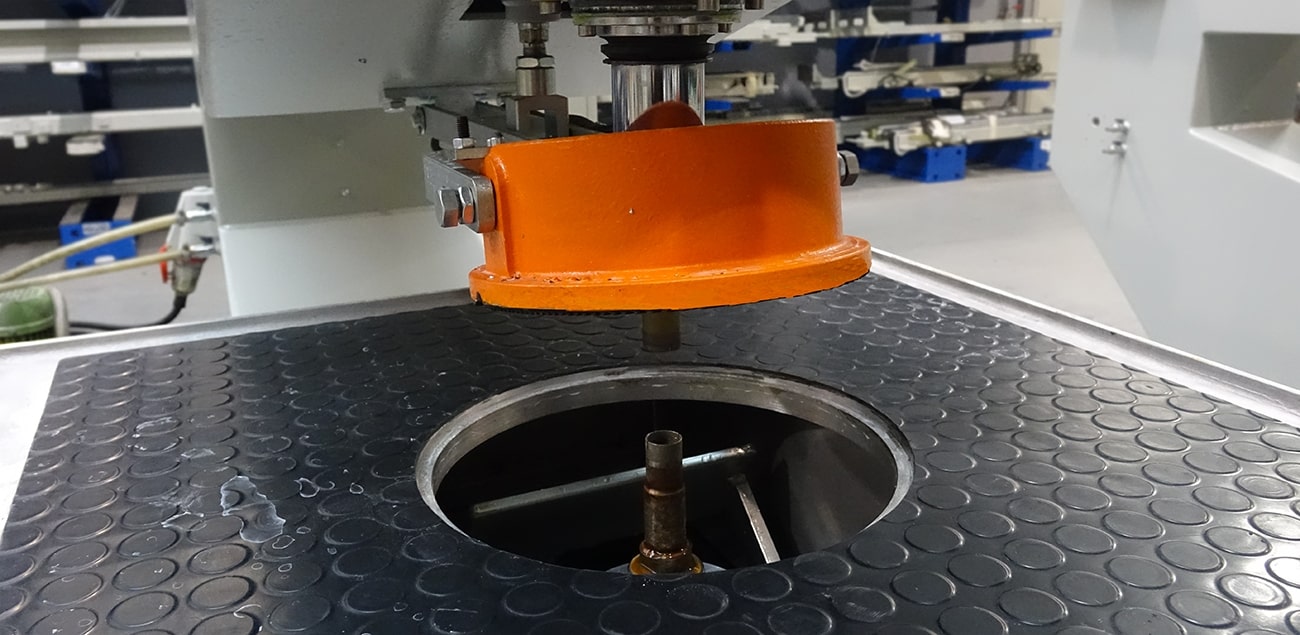

VT 1250

TIMELESS RELIABILITY:

The VT 1250 is a world-class double-headed drilling machine, trusted by thousands of companies for its proven durability, accuracy, and reliability.

Robust and Versatile

The VT 1250’s strong structure enables drilling of glass up to 25mm thick and supports intensive use, with a maximum hole diameter of 130mm. With a reach of 1250mm, it sets a benchmark for drilling, renowned for its quality, accuracy, and reliability.

User-Friendly Operation:

The VT 1250 features automatic head programming based on glass thickness, ensuring ease of use.

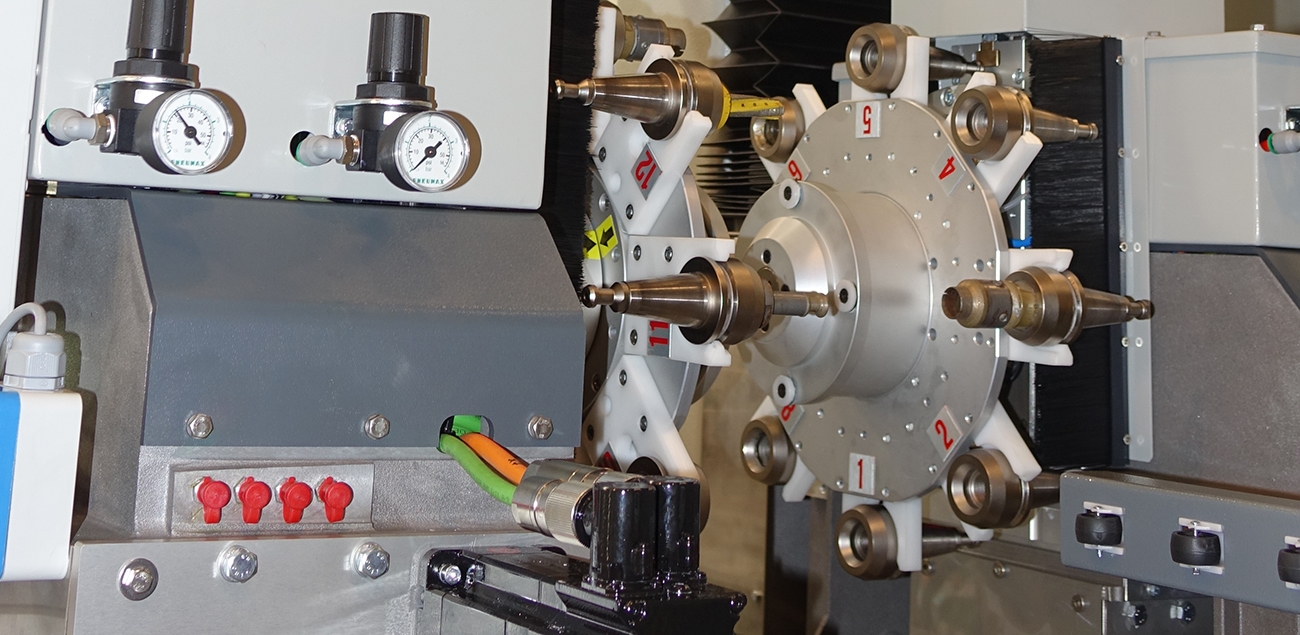

VDM 1636 CN:

VERTICAL NC MACHINE FOR DRILLING AND MILLING:

The newly introduced Bavelloni vertical drilling-milling machine, featuring a double head and opposing spindles, is capable of executing even complex processing cycles within a single workstation. To ensure high precision, the machine carries out milling operations while the glass remains stationary.

Exceptional Performance

The Bavelloni machine delivers top-tier performance, combining ease of use with speed and accuracy. This is achieved through advanced technical solutions, including powerful 5.5 kW electro-spindles, precise ball screw movements, efficient brushless motors, and a state-of-the-art numerical control system. The machine’s intuitive software ensures simple and user-friendly operation.

The VW 1600 OT features an open structure at the top, allowing it to accommodate glass sheets taller than 1600 mm and offering the flexibility to occasionally process larger panes.

Compact

The rotating double tool store with 8+8 positions enables to drill, counter-sink and mill in one single working station. Thanks to this new functionality, supplied as standard, it is possible to make holes and notches on parallelograms and off-square shapes.