With over 70 years of experience, we design, manufacture, and sell a comprehensive range of diamond and polishing tools for glass. Our 5,000 sqm facility produces 100,000 pieces annually, with 20,000 tools in stock for immediate delivery. .

Tools for glass

Bavelloni continually pursue the perfect grinding wheel and machine synergy for optimal performance. Our global network of expert distributors, technicians, and sales staff provides tailored advice for every glass processing need. We are committed to delivering the best experience possible.

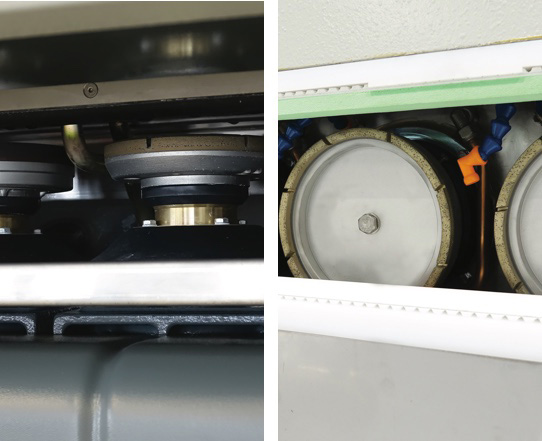

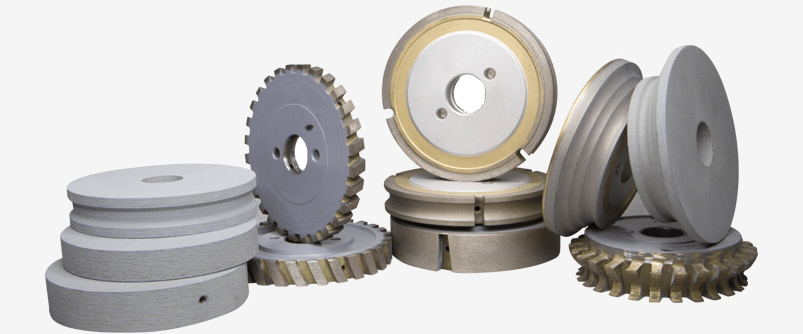

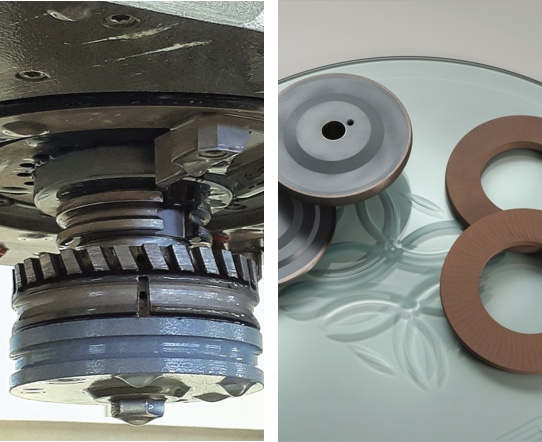

Metal and resin bond cup-wheels, arris wheels, polishing wheels for straight-line edging and double edging machines:

Complete range designed to increase productivity and performance while offering versatility of use for different applications.

- Set of standard tools and alternative solutions to satisfy different production needs on Bavelloni machines and of the major manufacturers on the market.

- Available in continuous, segmental crown and with slots.

- XtraSharp with innovative metal bond MB2: excellent performance, great self-sharpening capacity and quality finish.

- Polishing wheels with integrated metal plate, very easy to install.

- XtraShine and cerium rubber polishing wheels for excellent results.

Metal and resin bond cup-wheels, felts for bevelling machines:

Complete range designed to increase productivity and performance while offering versatility of use for different applications.

- High cutting capacity diamond wheels.

- High performance resin wheels with continuous crown and turbo long life sectors.

- Long-lasting wool and synthetic felts, also available with embodied plastic back plate.

- Easy to adjust, they allow to reach top productivity in the field.

- Complete sets for prismatic mirrors production.

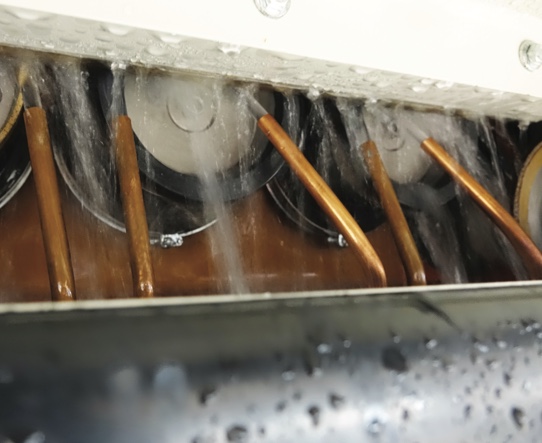

Peripheral wheels for double edging machines:

Our glass tools are highly reliable and offer key advantages such as grinding precision, durability, low reprofiling frequency, ease of use, and cost-effectiveness.

- Grinding wheels designed to provide constant cutting at high speed, even in demanding working conditions.

- Segmented grinding wheels for oscillating spindles, suitable for large removals, especially for processing laminated glass.

- Grinding wheels with customized shape for engraving the edge and the surface of the glass.

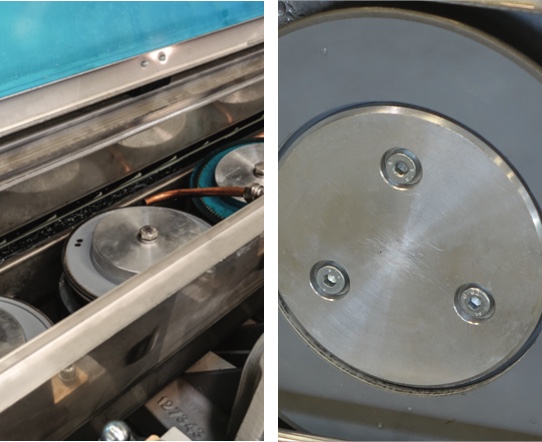

Diamond and polishing peripheral wheels for horizontal working centers

Our contouring wheels are designed to combine fast machining speeds, precise edge accuracy, enhanced safety, and robust durability. Additionally, our polishing wheels achieve a bright edge finish, even in a single pass.

- A wide range of peripheral diamond and polishing wheels, with sectors and continuous crown, of different diameters, shapes and grits, cover all the machining needs of the most common working centers on the market.

- BRILL-B: grinding wheels for polishing all profiles and thicknesses, long life, very effective on radii and curves.

- BRILL-R: for polishing straight and shaped engravings up to 12 mm wide.

- XtraSpeed bonded solutions: grinding wheels with up to 20% longer life than the standard ensuring high performance.

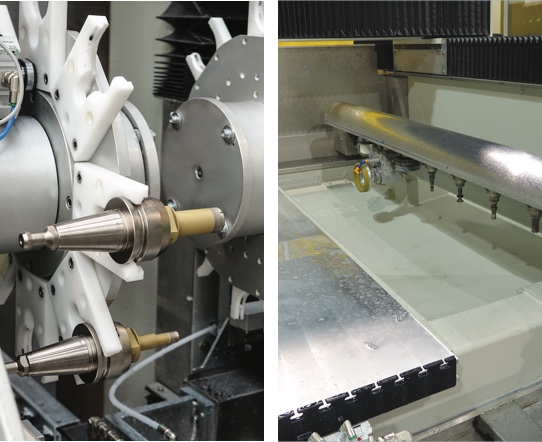

Diamond and polishing peripheral wheels for vertical working centers

We offer a variety of solutions born from our design expertise and extensive application experience. Our innovations bring enhanced efficiency and precision to edging processes on the latest generation of working centers.

- From roughing, to finishing, to polishing, a complete series of tools for the latest generation of vertical centers.

- XtraSpeed (with long-life bond) tools for optimal performance.

- BRILL-B polishing tools: excellent results and output.

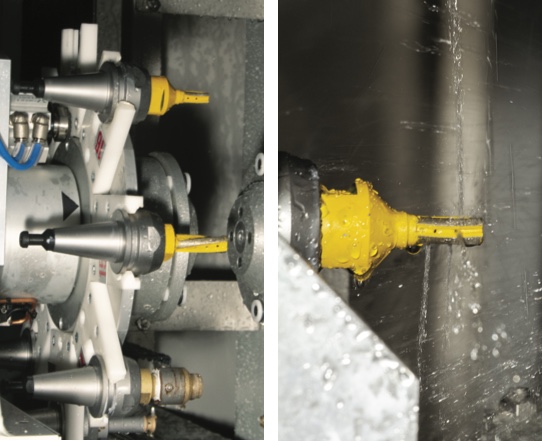

Milling cutters,combi-tools and cut-out wheels for working centers

Our product range includes top-notch tooling for milling straight flat edges, hinge cut-outs, pockets, or complex contours. Designed to give you a competitive edge, our milling tools enhance productivity and meet diverse processing needs.

- The cutting geometry allows to obtain a profiling with clean and precise edges and a constant finishing quality of the processed product.

- The high feed rate offers excellent productivity.

- The precise concentric rotation provides perfect stability at maximum speeds.

- The advanced design allows the best cooling and heat dissipation for a defect-free finished product.

- The long duration and the consistent, stable performance ensure low running costs.

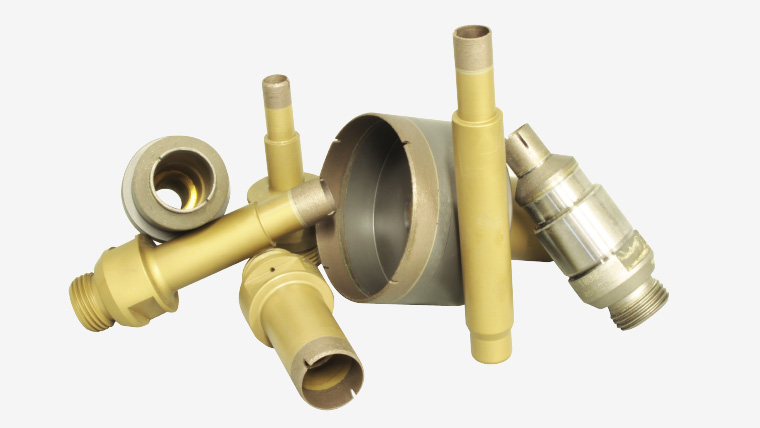

Core-drills and countersinks

Quality tools for the most demanding applications.

- Drills available in height 69 mm, 75 mm and 95 mm and various diameters. They can be equipped with countersink bits to accurately finish the edge of the hole.

- Suitable for use on working centers and on manual or semi-automatic drilling machines. Perfect to produce doors, balustrades and in architectural applications.

- Long life and stable performance over time.

- Excellent cutting capacity and working speed.