Bavelloni is a brand that made the history of flat glass grinding equipment. Since 1946, we have constantly supported innovation, understood as developing new products and production methods that can improve our customer’s results in terms of productivity and efficiency.

Working centers for glass

As one of the first manufacturers to recognize the potential of this machinery, Bavelloni has developed a high-end range of machines over the past 25 years, distinguished by exclusive solutions and unmatched reliability. Available in various models based on workable dimensions, Bavelloni NC machines can function as stand-alone units or be integrated with anthropomorphic robots in automated work stations.

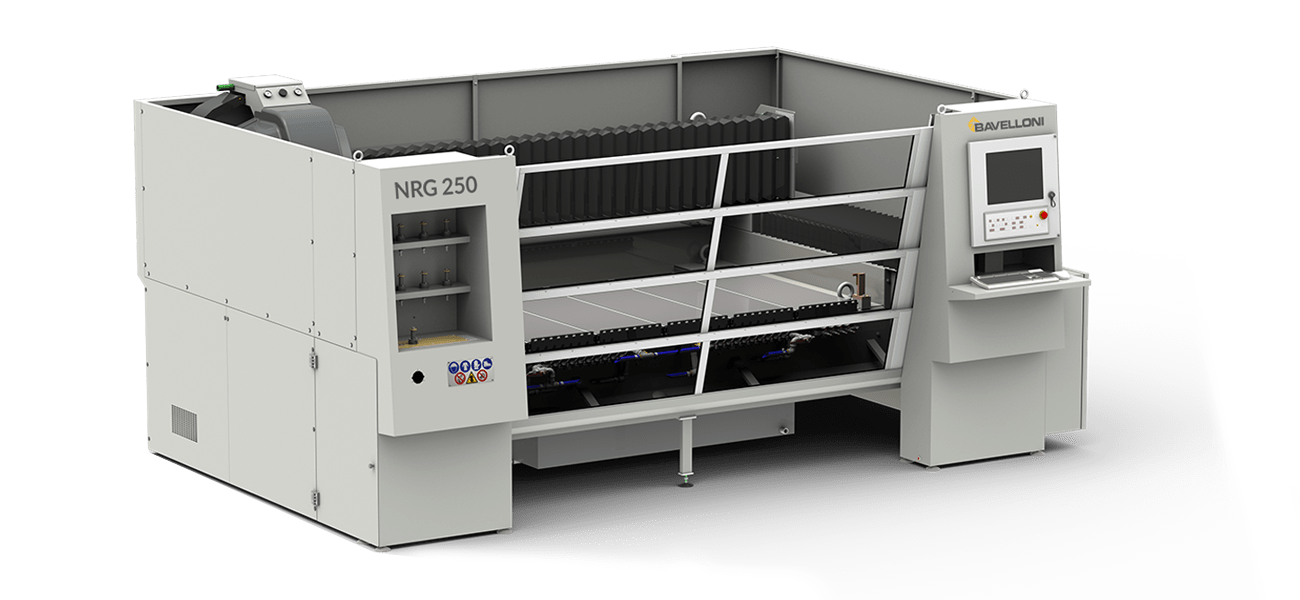

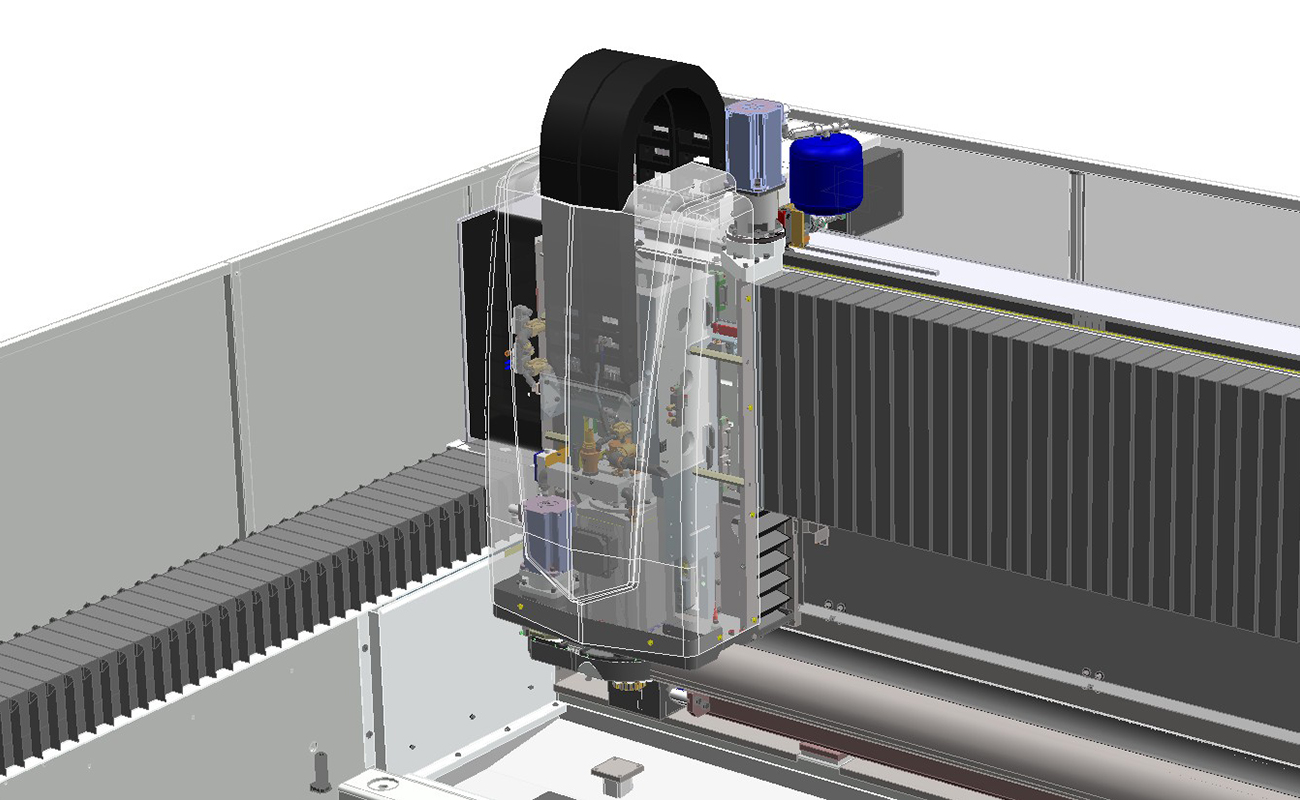

NRG 250

COMPACT AND EFFICIENT

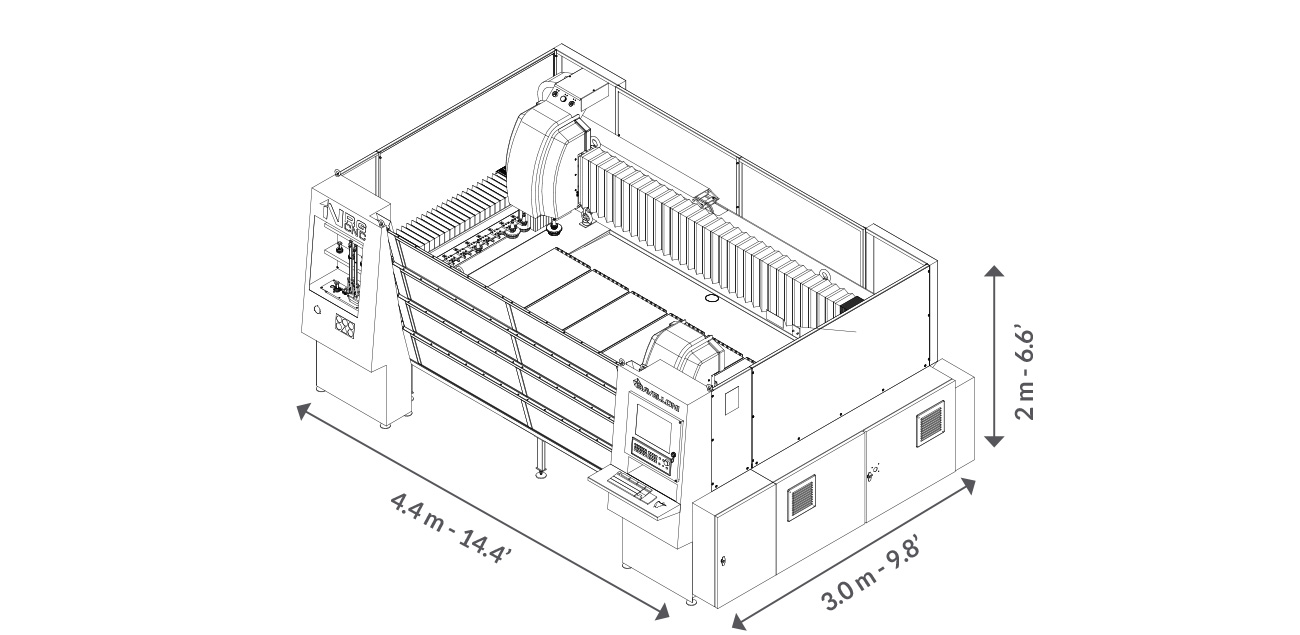

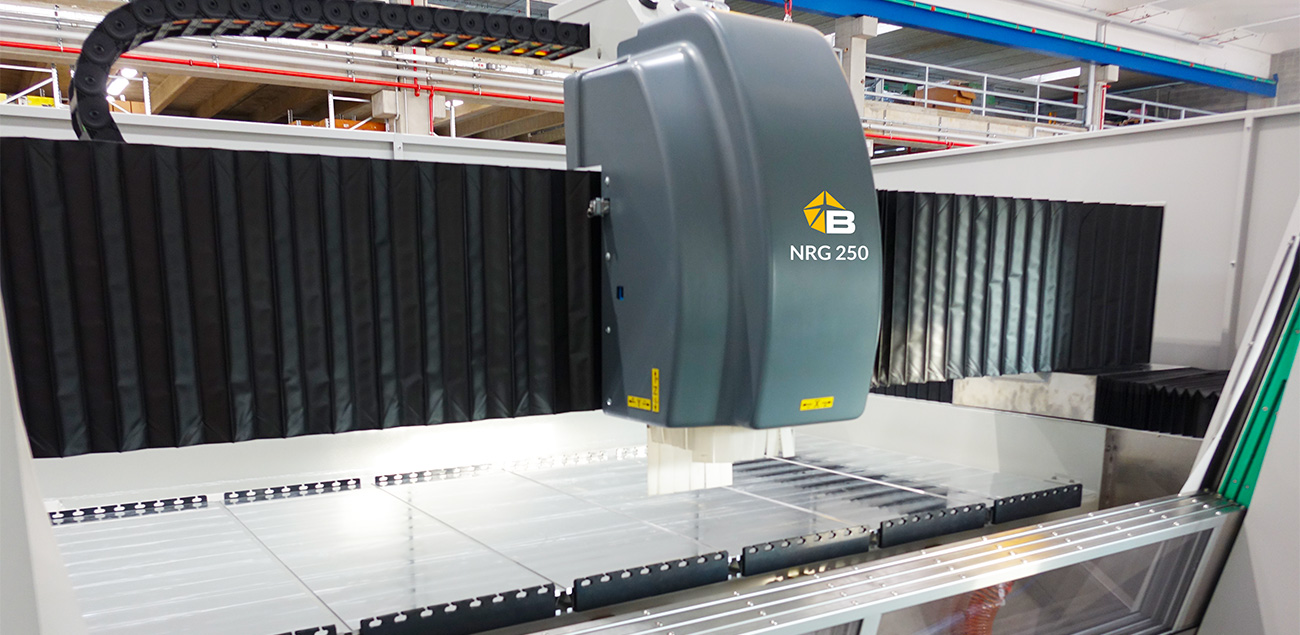

The NRG 250 is a three-axis CNC machine designed for high-speed processing, perfect for furniture, automotive, and appliance glass applications. Its rapid axis movement and responsive NC control system ensure optimal productivity in any working condition. With a compact design, the NRG 250 easily integrates into any manufacturing environment.

Practical and Ergonomic Design

The NRG 250 optimizes floor space with a footprint of just 12 sqm, including the electrical panel, while accommodating large workable sizes. Its automatic up-and-down door facilitates swift and efficient sheet handling.

Performances:

Despite being the smallest machine in its range, the NRG 250 is equipped with advanced features found in top models, including brushless motor-driven axes, a Gantry axis-driven bridge, and fully digital motor control. These features ensure dynamic movement and exceptional precision.

Built for Reliability:

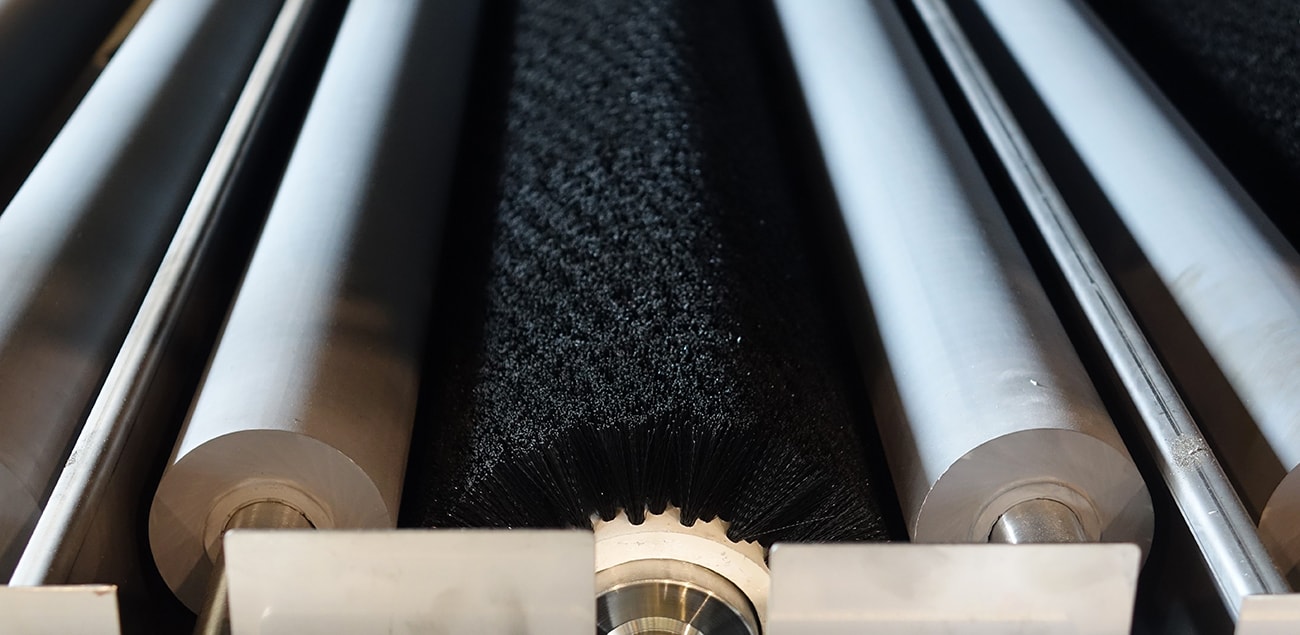

Bavelloni’s working centers, including the NRG 250, are built with an extremely robust structure and oversized operating devices such as guide rails, racks, and ball screws. This design philosophy ensures exceptional reliability and a long service life, and reducing operating costs.

Innovative Solutions:

Bavelloni working centers feature innovative solutions like the PAV patented system for automatic positioning of suction cups and centering devices, reducing tool change idle times. Additionally, integrated centering devices and a unique tool presetting device for automatic tool measurement enhance efficiency and precision.

NRG 330 and NRG 420:

UNLEASH CREATIVITY:

Our high-end working centers offer exclusive solutions and proven reliability to inspire your creativity. Available in various models with 3 or 4-axis configurations to suit different workable dimensions.

Door with automatic opening and closing

These models are equipped with a new door: automatic up and down movement. Glass loading and unloading have never been so easy.

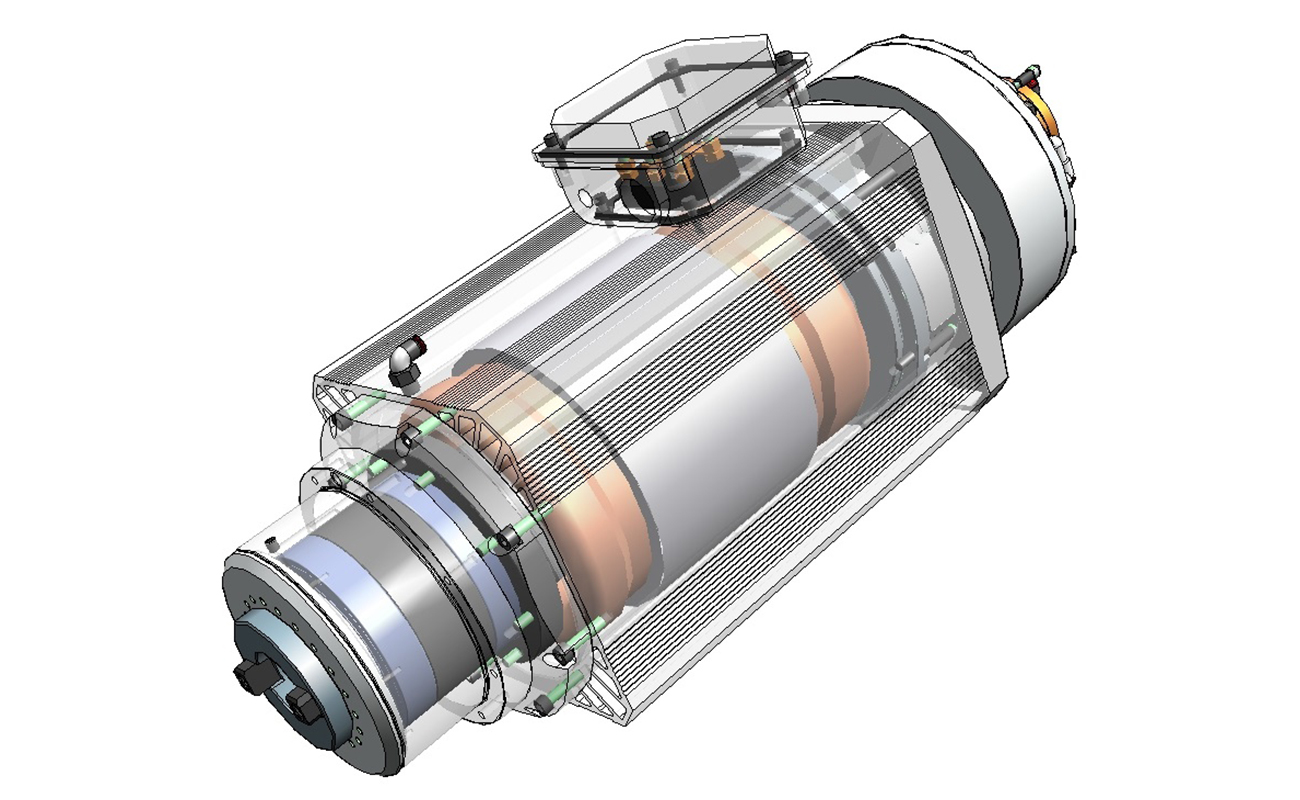

New Bavelloni spindle

The NRG 330 and NRG 420 models feature a newly designed electro-spindle, developed by the Bavelloni R&D team, ensuring extremely accurate quality control and expedited after-sales service.